The Latest in Thermal Energy Storage

As renewables gain a greater foothold in the energy system, the importance of energy storage is going to increase in kind. With the ongoing gradual shift away from traditional baseload energy sources, the development of efficient energy storage systems is imperative.

Like it or not, the U.S. energy mix is changing. According to the Energy Information Administration, U.S. fossil fuel production fell 7% from 2015 to 2016. Coal, in particular, decreased 18%, sitting at its lowest level since 1978. Even natural gas, which has been on an upswing in recent years due to the shale boom, fell 2% from 2015 to 2016.

Renewable energy production, on the other hand, increased 7% during that period, with wind and solar accounting for nearly a quarter of that jump.

The problem with this shift, of course, is the loss of baseload energy generation. The nation needs electricity 24 hours a day, not just when the sun is shining and the wind is blowing. Fortunately, the answer to this problem is known. Renewables must be combined with some form of energy storage, such as batteries, pumped hydro, or via thermal energy storage (TES, Figure 1).

On the surface, TES is a pretty basic idea. Energy is stored as heat in some form of medium for future use. However, delving further into the options and applications for TES reveals a much more complex picture.

Thermal Energy Storage 101There are three main types of TES systems, only one of which has significant commercial availability in the power sector. Compared to the other options, sensible heat storage is relatively inexpensive and much less complicated. Latent energy storage and thermal-chemical storage systems are expensive and as of yet largely experimental.

Sensible Heat Storage. The most widely used form of TES in the energy production sector is sensible heat storage. In a sensible heat TES system, a liquid or solid storage medium-such as water, molten salts, sand, or rocks-is heated or cooled to store energy.

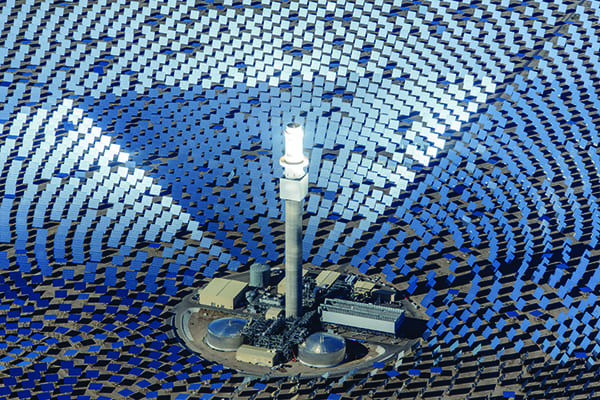

Sensible heat storage is widely utilized in concentrated solar power (CSP) applications where the use of TES enables a project to produce electricity well after the sun has gone down (see "Crescent Dunes Solar Energy Project, Tonopah, Nevada" in POWER's December 2016 issue). Generally, the medium of choice in CSP plants with TES is molten salts, which can withstand extremely high temperatures.

There are a variety of different CSP systems, each presenting unique energy storage requirements. While a direct TES system using molten salts is viable for a power tower system like that at the Crescent Dunes project (Figure 2), a parabolic trough project would likely require a slightly different TES system. According to the International Renewable Energy Agency (IRENA), nearly all new CSP plants operating or under construction are equipped with a TES system.

Latent Heat Storage. Latent heat storage is not as commonly used in the energy production sector, but recent developments have shown promise in some applications. Latent heat storage relies on the storage medium changing states, for example from solid to liquid. Latent heat storage mediums are often referred to as phase change materials (PCMs).

While sensible heat is the least expensive TES option, PCMs offer benefits worth pursuing if costs can be driven down. For example, sensible heat storage requires very large volumes of storage medium due to low energy density. PCMs offer an energy density roughly three times greater.

Thermo-Chemical Storage. As the name suggests, thermo-chemical storage (TCS) uses chemical reactions to store energy. TCS systems offer even greater energy density than PCMs.

Just about everything related to TCS is costly. For example, IRENA points out in a technology brief, the cost of the equipment from a thermo-chemical reactor is much higher than the cost of the storage material, which is not to say the cost of the material is insignificant.

Applications in Concentrated Solar PowerCSP has had a rough go of it as its sister technology, photovoltaic (PV) solar, has been enjoying a few good years of growth. According to the Solar Energy Industries Association, the PV market grew 97% from 2015 to 2016 as PV prices fell by nearly 20%. CSP, on the other hand, has not been able to keep up with the PV cost decreases.

To stay competitive with PV, CSP has to bring something unique to the table, and it has done so in the form of TES. "Thermal storage is required for any of these CSP technologies to move forward," Anoop Mathur, chief technology officer and founder of Terrafore Technologies, told POWER.

Using TES in CSP puts the technology in a position to hold a greater percentage of the energy mix someday, as PV and wind are not currently well-positioned to serve as baseload generation sources. With TES, a CSP plant could run 24 hours a day, a fact that SolarReserve has proved with its Crescent Dunes project in Nevada.

The Crescent Dunes project is a 110-MW plant located three hours outside Las Vegas. The plant boasts 1,100 MWh of energy storage, which can provide 10 hours of electricity at full load. The plant powers 75,000 homes during peak operation.

The project's molten salt power tower sits at the center of a massive field of mirrors, or heliostats, directing light to the top of the tower (Figure 3). The mirrors heat the energy storage medium directly, making the process more efficient than other systems that "bolt on" energy storage, SolarReserve CEO Kevin Smith told POWER. "I think the view in the solar thermal world is that the tower configuration with molten salt is the most efficient and cost-effective thermal storage for large-scale." The heat collected is used to generate steam that in turn drives a turbine generator.

SolarReserve's process pumps the molten salt up to the top of the tower where it is heated, making full use of the unique qualities of the salts. The molten salts used by SolarReserve remain solid until heated to about 450F, but once they are in a liquid form, they stay in that state at temperatures as high as 1050F. SolarReserve's "cold" salts are kept between 500F and 550F, meaning that the company's TES system has about a 500-degree working range.

In contrast, parabolic trough CSP projects heat an interim liquid, which in turn heats the molten salt. "The difficulty with that technology is the [fluid] that's utilized for heat transfer " has kind of a maximum temperature of maybe 700F or 750F. So they're operating from a 550F-to-700F, or 750F [range], which is only about a 200-degree delta, whereas we can transfer 500-degrees of delta into our molten salts. Essentially it means we're packing more energy into each pound of molten salt," Smith said. "It's kind of two or three times the energy stored in the salts."

With its 10 hours of storage, the Crescent Dune project can produce electricity 24 hours a day, though typically it only runs 12-14 hours a day. Generally, the plant is producing electricity for NV Energy from around 10 a.m. to 10 p.m. (Figure 4) simply because it is not needed for more than that.

|

| 4. Lighting up the night. Using sensible heat storage, the Crescent Dunes project is able to produce energy long after the sun has set, helping power the lights of Las Vegas. Courtesy: SolarReserve |

"In some markets, like say Chile or other markets, they really want a project like this to run 24 hours a day. The U.S. has a pretty diverse mix of power; there's still a fair amount of coal-burning power projects out there and a lot of nuclear, and those facilities have to run 24 hours a day," Smith noted.

However, as the nation's energy mix continues to change, SolarReserve predicts that Crescent Dunes could be operating for longer stretches. "Longer-term, a lot of [coal and nuclear] will be phased out, and as the U.S. markets change over the long-term, we may see that we could be operating more 24 hours a day. But for right now, it's more the peak demand periods 8, 10, 12, 14 hours a day of generation and typically well into the evening hours," Smith said.

Implications for the FutureWhile sensible heat transfer currently dominates the TES field, there is a lot of research and development activity in PCMs and TCS. One such project, an encapsulated PCM developed by Terrafore Technologies, has received significant support from the Department of Energy and may be on the verge of commercialization.

As noted, PCMs hold an advantage over sensible heat storage mediums due to their increased energy density. The best way to take advantage of PCMs, Mathur said, is to encapsulate them. However, doing so is no easy task.

"The big issue of encapsulating is how do you encapsulate a solid which expands almost 20%?" he said. "That means you have to have a capsule, think about a ball partially filled with salt, how do you make that? You cannot open it and fill part of it and seal it because sealing becomes an issue."

The answer, according to Mathur, is polymers. "I thought about it, dreamed about it, so I said why can't we put some kind of a polymer on top of my capsule, on the salt? Then put my shell material, and then heat it, and then the polymer will disappear, leaving a void behind," he explained. "So that gives it expansion volume. It is a chemical way of creating a void inside the shell."

Terrafore's system improves on the traditional sensible heat system in that it requires less material to do the same job. Where the molten salt system used at Crescent Dunes requires two large tanks, one for the "cold salt" and one for the heated salt, the Terrafore system requires only one tank and less material.

Within the tank, three different salts would be stacked. At the top are salts with the highest melting point and at the bottom are salts with the lowest melting point, with a layer of salts with a mid-range melting point in the middle. The system uses a thermal transfer fluid, which flows from the solar receiver to the top of the tank where it then flows through the stacked bed of capsules, heating them in turn as the fluid slowly cools. Once it reaches the bottom of the tank, the thermal transfer fluid is pumped back to the solar receiver.

That cycle continues until the stored energy is needed, at which time the heat transfer fluid is pumped from the tank into the power block where steam is generated to drive a turbine.

Finding a Good MatchMathur doesn't see his PCM process being adopted at large-scale CSP projects like Crescent Dunes in the very near future, but he hopes that at some point it might make its way into that sector. For now, he believes the best place for his technology to enter the market is in distributed CSP.

Working with a company in Sweden, Mathur believes he may have found a good match. "They have developed a dish Stirling system, which can operate at about 800-900C, but it works exactly like a PV-when the sun shines it generates electricity. So they cannot be competitive with PV because PV costs are so low. Now, if they can put storage with it, they become competitive with a dispatchable standpoint," he said.

For the time being, SolarReserve is happy with the technology it has developed. The company currently has a number of projects under development around the world, all based on the same technology used at Crescent Dunes. "The core technology, which is our receiver technology, does not really need to be modified very much when we go from location to location," Smith explained.

However, that doesn't mean the company's leadership isn't keeping an open mind. "We're keeping our eye on other options out there on thermal storage and other materials that we can utilize," Smith said, "but right now we really don't see anything that's on the horizon near-term that can be done on a commercial scale." a-

-Abby L. Harveyis a POWER reporter.

The post The Latest in Thermal Energy Storage appeared first on POWER Magazine.