The World’s Largest 3D Metal Printer Is Churning Out Rockets

I'll never forget the first time I saw a rocket materialize before my eyes.

In October 2018, I stood in a small room and watched a massive robotic arm move elegantly around a large metal shape, which was rapidly growing larger as I gazed at it. The arm precisely deposited a stream of liquid aluminum to build up the structure, layer by layer, while two other arms waited, with finishing tools at the ready. I was standing in the Los Angeles headquarters of the upstart rocket company Relativity Space, staring in awe as a piece of its first launch vehicle, the Terran 1 rocket, came into existence.

I had only recently arrived at Relativity as the first engineer hired for its avionics department. Relativity offered quite a change of scenery from my prior jobs, even though the other companies I'd worked for also built rockets. But they did so in massive rooms, measuring thousands of square meters, enough to hold ranks of bulky manufacturing tools such as metal rollers, dome spinners, and friction-stir welding machines. At Relativity, though, most of the launch vehicle is built inside the small room where I was standing, which measures just 9 meters across.

The room contained Stargate, the largest metal 3D printer in the world. Relativity invented the Stargate printer for the audacious purpose of 3D printing an entire rocket that's intended to fly to low Earth orbit. We hope our rockets will eventually fly even farther. Perhaps one day we'll ship our 3D printers to Mars, so rockets can be constructed on the Red Planet. From there, who knows where they'll go.

Does this sound crazy? Crazy ambitious, maybe. But plenty of people are taking our idea seriously. Four commercial customers have signed up for launches to Earth orbit beginning in early 2021. The U.S. Air Force has approved our request to build a launch site at Cape Canaveral, the famed Florida facility that launched many historic human spaceflight missions. And NASA has leased us a building at its Stennis Space Center, in Bay St. Louis, Miss., where Relativity will build a factory capable of turning out 24 rockets per year. Such mass production will represent a revolution in rocketry. By embracing additive manufacturing-that is, 3D printing-we believe we can pull it off.

Video: Relativity SpaceLaunching a rocket into orbit is a binary proposition: Either you succeed or you fail. During the roughly 10-minute flight from launchpad to space, a mind-boggling array of systems must work together perfectly-plumbing, avionics, software, pyrotechnics, and pneumatics, to name just a few. If any component fails, the whole endeavor can literally come crashing down.

The cost of a rocket is not determined by its raw materials; those are pretty cheap. It's largely driven by the human labor needed to work those materials into usable components and verify that they will function for flight. There are two ways to reduce these labor costs: You can reduce the total number of parts in a rocket so less labor is needed, or you can change manufacturing processes to reduce the need for human minds and hands.

Blue Origin, SpaceX, and Virgin Orbit-companies that are leading the charge in the new commercial space sector-have tried a combination of these two methods to reduce labor costs. But these companies' reliance on traditional "subtractive" manufacturing techniques, in which chunks of raw material are cut down and shaped, limits their options. The companies have automated much of their supply chains, yet they still have tens of thousands of parts to track through complex manufacturing systems. Automating the manufacturing process has reduced human labor, but it requires expensive customized tooling that matches the dimensions of a particular rocket.

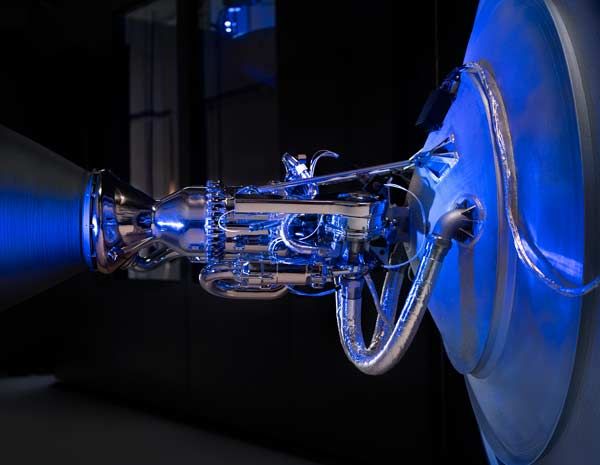

Photos: Relativity Space Simplify, Simplify, Simplify: Relativity Space makes rocket science look easy. Its Aeon engine, shown in side view [left] and from the bottom [right], is composed of three 3D-printed parts. A classic rocket engine is assembled from thousands of parts.

Photos: Relativity Space Simplify, Simplify, Simplify: Relativity Space makes rocket science look easy. Its Aeon engine, shown in side view [left] and from the bottom [right], is composed of three 3D-printed parts. A classic rocket engine is assembled from thousands of parts. Relativity approaches the labor challenge head on by leveraging additive manufacturing to print complex components, using a single operation to turn raw material into finished product. This approach dramatically reduces part count because one of our components is often the equivalent of dozens of small parts made via traditional manufacturing. Our process also relies on our 3D printers rather than fixed tooling, which enables us to be nimble and inventive. We can make large design changes with relatively little cost or time lost.

Rocketry operates on a different scale than other manufacturing sectors. Consider that the Volkswagen plant in Wolfsburg, Germany, turns out about 3,500 vehicles per day. In contrast, any aerospace company that could build 100 rockets in a year would be monumentally successful. What's considered high-volume production in rocketry is relatively low-volume in other industries. That means that additive manufacturing can have a big impact on the industry. Because only dozens or hundreds of a particular part may be needed in a year, it doesn't necessarily make sense to invest in highly optimized tooling to turn out that part in mass quantities-the tools might not pay for themselves before the part becomes obsolete.

Making a new part using a 3D printer requires little to no up-front cost. For example, one of our Stargate printers can produce a 2-meter-diameter propellant tank followed by a 3-meter-diameter tank with minimal downtime. Rather than having to retool an entire manufacturing facility to fabricate the next piece of hardware in the queue, we have to make only a few software-configuration changes.

Our company's cofounders, Jordan Noone and Tim Ellis, met in college at the University of Southern California's Rocket Propulsion Laboratory, in Los Angeles. Noone went on to work at SpaceX and Ellis at Blue Origin before they got back together and formed Relativity in 2015.

Both of their former companies use additive manufacturing to build some rocket components, but Noone and Ellis wanted to take the approach much further. They saw an opportunity to completely rethink how rockets are designed and manufactured. By simplifying designs and production processes, they figured, they would also simplify the mental labor, the "cognitive overhead," involved in building a rocket.

Photo: Relativity Space Start to Finish: Above, engineers keep an eye on the printing process, which is highly automated.

Photo: Relativity Space Start to Finish: Above, engineers keep an eye on the printing process, which is highly automated. Rockets typically have a huge number of individual parts: The space-shuttle system, for example, consisted of 2.5 million moving parts. All the pieces must fit together just right and can't unexpectedly add up to an out-of-tolerance assembly. Every part must be manufactured, tested, installed, and tested again. More work ensues if a part needs to be fixed. And all these processes require engineers, technicians, tooling, and paperwork.

With additive manufacturing, you can design parts that incorporate several pieces that would traditionally be manufactured separately and assembled. Fewer parts means fewer interfaces and fewer chances for something to go wrong.

Our approach to designing and building our rocket engine is a case in point. Inside a typical rocket engine you'll find an injector that mixes the fuel with the oxidizer as they enter the combustion chamber, where an igniter starts the fire. The combustion produces hot gas, which moves through a nozzle to create thrust. It sounds simple in principle, but the reality is staggeringly complex. Consider that Rocketdyne's F-1 engine, which launched Saturn V rockets during NASA's Apollo program, contained a combustion chamber and nozzle assembly composed of more than 5,000 individually manufactured parts (and that's not including the injector).

Relativity's engine, Aeon 1, is a different story. To build the engine, we employ commercial 3D printers that use a process called direct metal laser sintering, in which a laser fuses together particles of metal powder, creating the required structure layer by layer. The simplest variant of the engine, a pressure-fed version that uses pressurized gas to push the fuel and oxidizer from their tanks into the combustion chamber, is manufactured by pressing the printer's on button three times (to print three parts). And we're going further: We expect commercial printers to become available soon that will allow us to print the injector, igniter, combustion chamber, and nozzle as a single part.

Photo: Relativity Space Made From Scratch: Jordan Noone, Relativity Space cofounder, stands in front of the company's newest 3D printer as it builds a fuel tank for the Terran 1 rocket. The additive manufacturing approach makes it easy for Noone's team to iterate on their designs.

Photo: Relativity Space Made From Scratch: Jordan Noone, Relativity Space cofounder, stands in front of the company's newest 3D printer as it builds a fuel tank for the Terran 1 rocket. The additive manufacturing approach makes it easy for Noone's team to iterate on their designs. We use that pressure-fed engine for development and testing; the engine that will eventually fly will use turbopumps instead of simple pressurized gas to move the fuel (liquid methane) and oxidizer (liquid oxygen). These turbopumps, which are better suited for rockets with large fuel tanks, will increase the part count, but the manufacturing process will still be vastly simpler than any before.

Many rocket engines use a technique called regenerative cooling, in which liquid fuel is pumped through cooling channels around the combustion chamber to suck heat away. In a traditional manufacturing and assembly process, a thick piece of copper is shaped by spinning it rapidly while applying pressure to form the inner contours of the combustion chamber. It is then milled to create intricate cooling channels on the outside. A strong outer jacket is then brazed onto the copper structure, and a fuel-inlet manifold is welded onto the outer jacket. The whole engine assembly requires finish machining to hold tight tolerances where things fit together. Each of these processes is an opportunity for design or manufacturing error. The Aeon engine also uses regenerative cooling, but its combustion chamber is created in a single print. What's more, 3D printing enables us to incorporate many more tiny cooling channels than can be produced by milling the metal.

Photo: Relativity Space Stage Two: Cofounders Tim Ellis [left] and Jordan Noone inspect a finished product: the Terran 1 rocket's second stage, composed of a fuel tank, engine, and nozzle extension.

Photo: Relativity Space Stage Two: Cofounders Tim Ellis [left] and Jordan Noone inspect a finished product: the Terran 1 rocket's second stage, composed of a fuel tank, engine, and nozzle extension. It's normally a monumental task to get a single engine designed, fabricated, and on the test stand. This process takes 10 to 12 months using traditional methods. A major redesign takes almost as long. But we're able to iterate much faster. In our initial tests of the Aeon engine, we tried out five versions within 14 months, firing the engines more than 100 times.

As NASA astronaut Donald Pettit explained in his brilliant article "The Tyranny of the Rocket Equation," published on the NASA website, getting out of Earth's gravity well is not an easy task. Rockets are largely empty vessels waiting to be filled with fuel. Pettit explains that 94 percent of the mass of a can of soda comes from the soda, and 6 percent from the can. The space shuttle's external fuel tank was 96 percent fuel and 4 percent tank, an impressive improvement over soda-can technology when you consider that the fuel tank held cryogenic liquids that had to be pumped out at a rate of 1.5 metric tons of fuel per second.

The entire Terran 1 rocket is designed for simplicity. The tanks that hold the fuel and oxidizer are "autogenously pressurized," which means a small percentage of vaporized fuel and oxidizer is pumped back into their respective tanks to replace the volume of liquid as it drains. To continue Pettit's analogy, picture an unopened soda can, which is rigid and strong despite the thin shell of the can; once the can has been opened, though, it can be crushed with ease. Similarly, rockets use internal pressure to help create a lightweight yet strong vehicle.

These autogenous systems on Terran 1's tanks eliminate the need for the special pressure vessel that many rockets use inside their fuel and oxidizer tanks. Those pressure vessels hold inert gases such as helium at extremely high pressures until they're ready to be released into the tank to provide internal pressure. These vessels are notoriously difficult systems to engineer and manufacture and have been involved in several rocket failures in the last decade, including the explosion of a SpaceX Falcon 9 rocket in 2015.

Commercial printers that use metal laser sintering are suitable for manufacturing our engines, but they wouldn't be practical for producing the tanks. Those printers work by selectively melting the desired portions of metal powder to create the solid material in each layer of a part. Because the powder bed needs to be flat and even for each layer, the entire work space of a printer must be filled with powder, regardless of how much material will actually be solidified. Most of that powder can be recycled, but some is lost on every print. Producing a tank using a laser sintering printer would require an unrealistic amount of metal powder and would be very slow.

Photo: Relativity Space Blazing The Trail: The Stargate printer is the world's first 3D printer that can make massive metal objects like a rocket's fuel tank.

Photo: Relativity Space Blazing The Trail: The Stargate printer is the world's first 3D printer that can make massive metal objects like a rocket's fuel tank. That's why we designed and built Stargate, our enormous 3D printer of a different kind. It uses an existing technique called directed energy deposition but operates at a scale never before seen. The printer feeds a metal wire into the deposition area and uses energy (typically a powerful laser) to melt the wire, building up printed parts layer by layer.

Stargate places molten metal only where it is needed to build the structure, which significantly cuts down on wasted material. It uses three massive robotic arms, one of which terminates in the printer head that feeds out the wire; the two others hold working tools for finishing the printed component. We also wrote proprietary software to manage the "path planning" involved in turning a design into detailed instructions for the robotic arms.

Stargate has a few limitations. Its robotic arms move its working tools through free space as it prints, which means the geometries that can be printed are constrained by the kinematics of the robotic arms-they can reach only so far and must avoid colliding with the printed structure. And as the wire melts, the bead size resulting from the welding process sets the minimum resolution of the print. But these restrictions aren't serious when it comes to large pressure vessels and structural elements.

Our Stargate printer is a novel piece of technology, and we believe it opens up new frontiers in aerospace manufacturing. But the novelty of this printing process also means that we cannot rely on preexisting material data or process parameters to achieve high-quality products. Relativity has in-house metallurgists who are honing the process, ensuring that our components meet the strict quality standards for aerospace hardware.

Video: Relativity SpaceIn traditional aerospace manufacturing, a design change can require almost a year of retooling and adjustments. Because hardware changes take so long, the avionics department is usually the most agile part of an aerospace company. Avionics teams (which handle the electronics that manage the rocket's guidance, navigation, communications, and more) are accustomed to implementing last-minute software changes to fix issues on other parts of the vehicle.

The situation is completely reversed at Relativity, where the hardware team can make substantial design changes and still produce a new tank or engine within days. They can revise their plans so quickly that they challenge the avionics team's ability to produce printed circuit boards (PCBs) and construct the cable harnessing that connects all the electronics and wiring. Avionics has to adapt to an ever-changing and improving rocket.

That's why we designed the avionics of the Terran 1 rocket to be as modular as possible. We assume that sensors and actuators will be changed, and so we designed the electronics in a way that would limit the impact of such modifications. To accomplish this feat we devised a few proprietary methods of busing, minimizing the number of connectors and pins. We make every effort to reduce the amount of harnessing, which is one of the least reliable parts of the avionics on a rocket-every connection of every wire is a potential failure point. Wherever possible, we use standards such as the Controller Area Network bus protocol (for enabling communication between microcontrollers and devices) and Ethernet, and thus can use existing industry tools for testing and development. This approach means we don't waste time hunting for bugs in custom protocols and can instead focus on ensuring the proper operation of our avionics in their specific use cases.

As we consider each small design choice in the avionics systems, we aim for global rather than local optimization. For example, we use standard tools that automate electronics design, such as Altium Designer, to create basic spaceflight-qualified circuits that we can use in multiple ways throughout the rocket. We call these "bread and butter circuits," and we use them in voltage converters, processors, sensor interfaces, and other components. When our engineers tackle a new problem, they build on the work that's already been done, rather than starting from scratch. While this may sound like a commonsense approach, you'd be surprised at how many rockets contain a complicated assortment of circuit designs simply because different engineers solved the same problem in slightly different ways.

Photo: Relativity Space The Build: A printer head [top] deposits metal wire and melts it into place to build up a tank, line by line [middle]. The tank connects to the engine and nozzle extension [bottom] to form the rocket's second stage.

Photo: Relativity Space The Build: A printer head [top] deposits metal wire and melts it into place to build up a tank, line by line [middle]. The tank connects to the engine and nozzle extension [bottom] to form the rocket's second stage. Another example can be found in our firmware. For internal communications within our avionics boxes, we don't always use a protocol that's optimized for PCBs, which would provide tiny benefits in performance and mass. Instead we sometimes use a protocol that we also use for external box-to-box communications. This method cuts the cost and time of firmware development considerably. What's more, it gives us flexibility for our design solutions: We can make changes within a centralized box, or we can add on some last-minute sensor in the harnessing, but the software doesn't know the difference. This approach may not be optimal for the avionics systems viewed in isolation, but it gives us many advantages elsewhere in regard to designing, building, and flying rockets.

Relativity CEO Ellis often reminds us that we should put at least as much thought into designing and producing our company's culture as we do into designing and building our rocket. Relativity is focused on maintaining flexibility, so experimentation is encouraged. This attitude is antithetical to the culture of traditional aerospace companies, which try to lock down their designs as soon as possible. We have an aggressive goal-to launch Terran 1 by early 2021. So we leverage our modular approach to swap out pieces, and we're constantly tweaking to optimize our designs for the world's first 3D-printed rocket.

The Terran 1, which is about 30 meters tall and 2 meters wide, is intended to launch modestly sized satellites into low Earth orbit at a cost that is radically lower than competitors can offer. It will enable smaller companies to book the whole payload of a rocket and send it to their desired orbit on their own schedule, rather than having to piggyback on the flight of a bigger rocket whose destination orbit and schedule is controlled by another company.

Relativity Space may stumble, but with our emphasis on design and manufacturing flexibility we can afford to fail many times over. We learn from every failure and forge ahead. We're watching the future of rocketry materialize before our eyes.

This article appears in the November 2019 print issue as "3D Printing a Rocket."

About the AuthorBryce Salmi is the lead avionics hardware engineer for the Los Angeles aerospace startup Relativity Space.