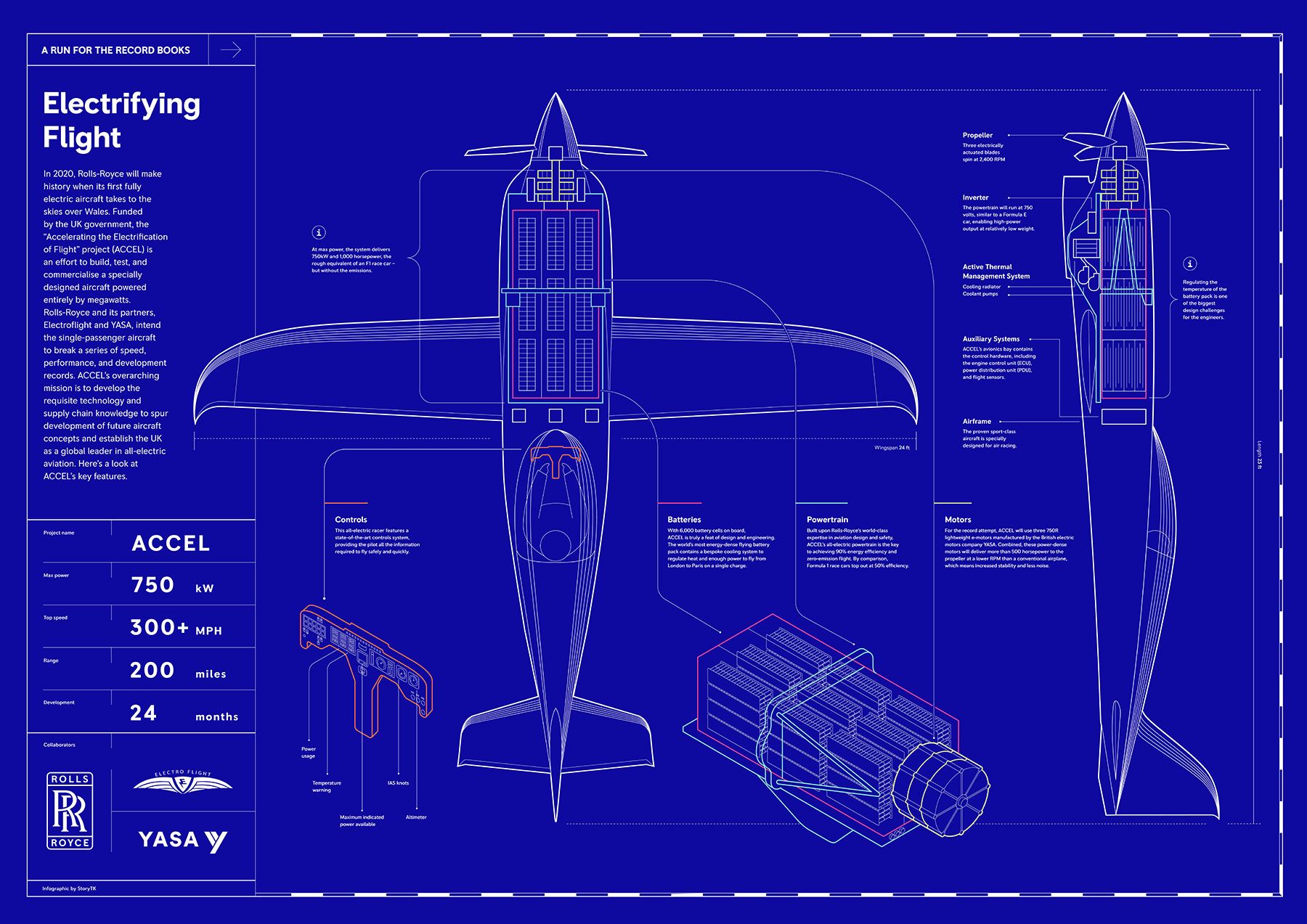

The Battery Design Smarts Behind Rolls Royce’s Ultrafast Electric Airplane

Dozens 0f electric general aviation projects are underway around the world, not counting the urban air taxis that dominate the electric propulsion R&D scene. The first all-electric commercial aircraft, a seaplane intended for short flights, completed a 15-minute test flight in December.

Shortly after, luxury icon Rolls Royce unveiled what it hopes will be the world's fastest electric aircraft. The current speed record for that type of plane is 335 kilometers per hour (210 mph). The new one-seater craft, slated to fly this spring, will top out at 480 km/h (300 mph). It should also be able to fly from London to Paris, about 320 km (200 miles), on a single charge.

That's thanks to "the world's most energy-dense flying battery pack," according to Rolls Royce. The aircraft has three batteries powering three motors that will deliver 750kW to spin the propellers. Each 72 kilowatt-hour battery pack weighs 450kg and has 6,000 densely packed lithium-ion cells.

Getting all this power on board wasn't easy, says Matheu Parr, project manager for the ACCEL project, short for Accelerating the Electrification of Flight. Careful thought and engineering went into each step, right from selecting the type of battery cell. Lithium-ion cells come in many forms, including pouches as well as prismatic and cylindrical cells. Cylindrical ones turn out to be best for holding a lot of energy and discharging it quickly at high power, he says.

Next came the critical task of assembling the cells into a pack. Rolls Royce's partner, Electroflight, a startup specializing in aviation batteries, began that effort by analyzing innovations in the relatively new all-electric auto-racing space.

"Really, the challenge for electric aviation is one of packaging," Parr says. "So we've looked at how Formula E [air racing] tackles packaging and then taken it a step further." By using lightweight materials-and only the bare minimum of those-the Formula E teams manage to cut their planes' packaging-to -battery cell weight ratio in half compared with the amount of battery packaging an electric car has to carry around for each kilogram of battery cell.

Illustration: StoryTK/Rolls Royce

Illustration: StoryTK/Rolls Royce The high-power, closely packed cells get pretty hot. So, designing an advanced active-cooling system was important. Instead of the air-cooling used in car batteries, Rolls Royce engineers chose a liquid-cooling system. All the cells directly contact a cooling plate through which a water-and-glycol mixture is piped.

Finally, the engineers built in safety features such as an ultra-strong outside case and continual monitoring of each battery's temperature and voltage. Should something go wrong with one of the batteries, it would automatically be shut off. Better still, the airplane can land even if two of its three batteries are turned off.

The ACCEL battery comes out to a specific energy of 165 watt-hours per kilogram, which puts it on par with the battery pack powering the Tesla Model 3. That's still a long way from the 500 Wh/kg needed to compete with traditional jet-propulsion aircraft for commercial flights (aviation batteries are not expected to store that much energy per unit mass until 2030). For now, Rolls Royce and others believe all-electric propulsion will power smaller aircraft while larger planes will have hybrid fuel-electric systems. The company has teamed up with Airbus and Siemens to develop a hybrid airplane.

With its high-speed racing aircraft, Rolls Royce wants to pioneer the transition to the "third age of aviation, from propeller aircraft to jet aircraft to electric," says Parr. The project will also provide know-how that will shape future designs. "We're learning an awful lot that we want to see packed into a future aircraft. Innovations in the battery and system integration, packaging and management will all help us shape any future electric product, be it all-electric or hybrid."