Cranes Lift More Than Their Weight in the World of Shipping and Construction

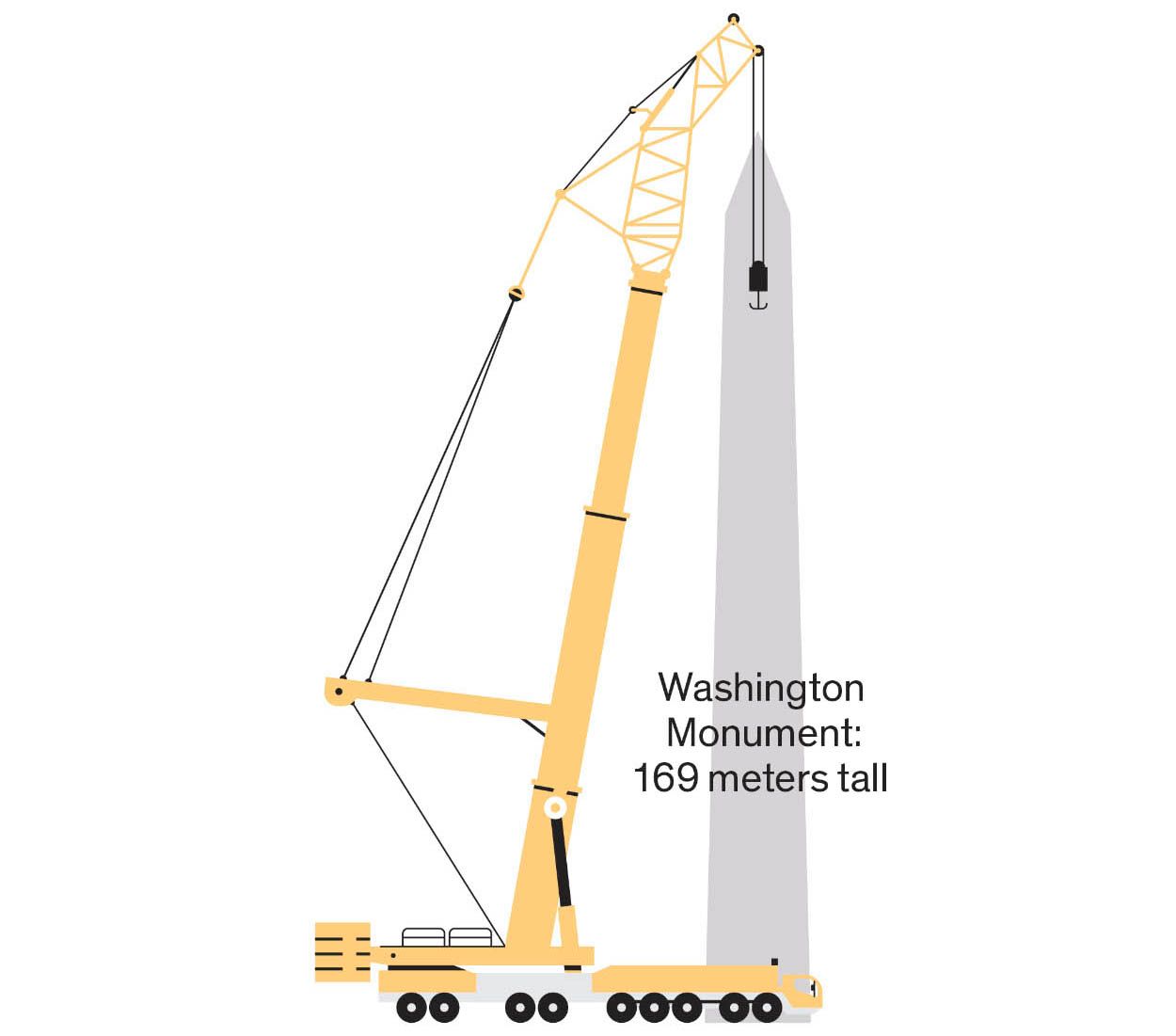

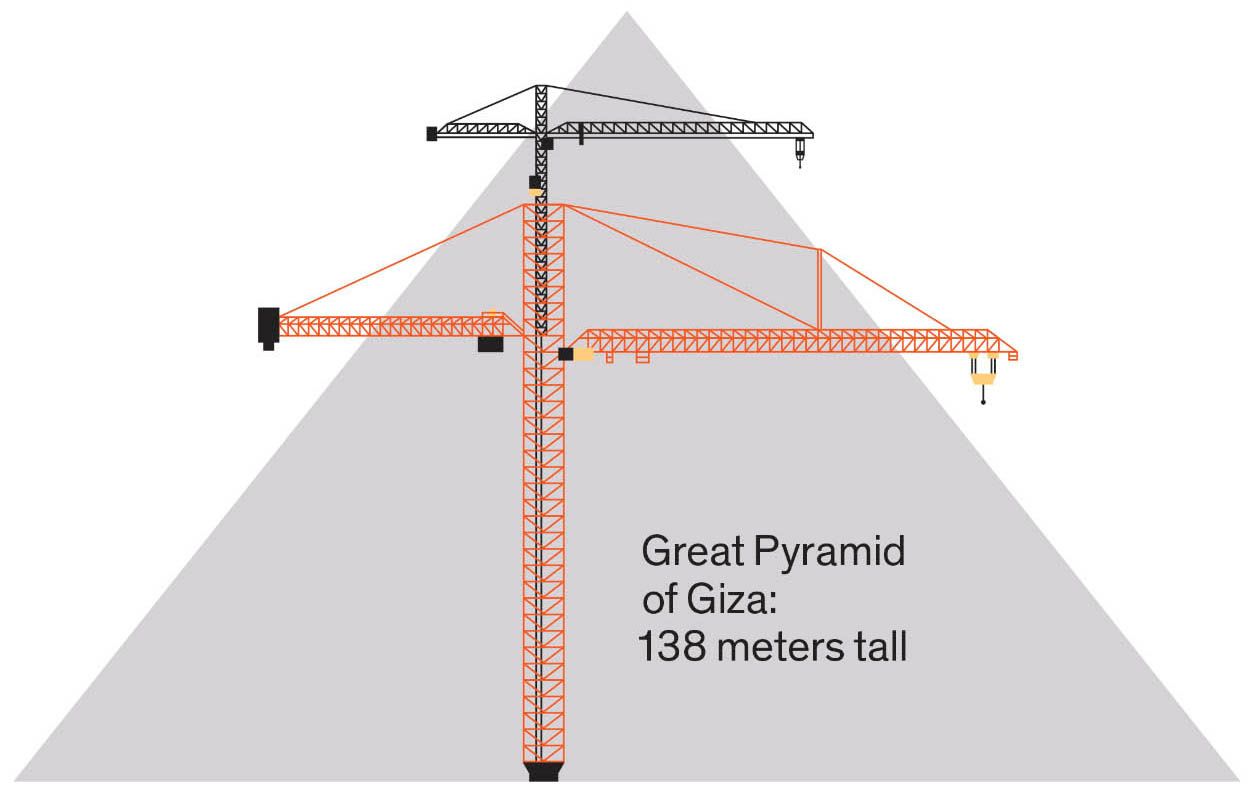

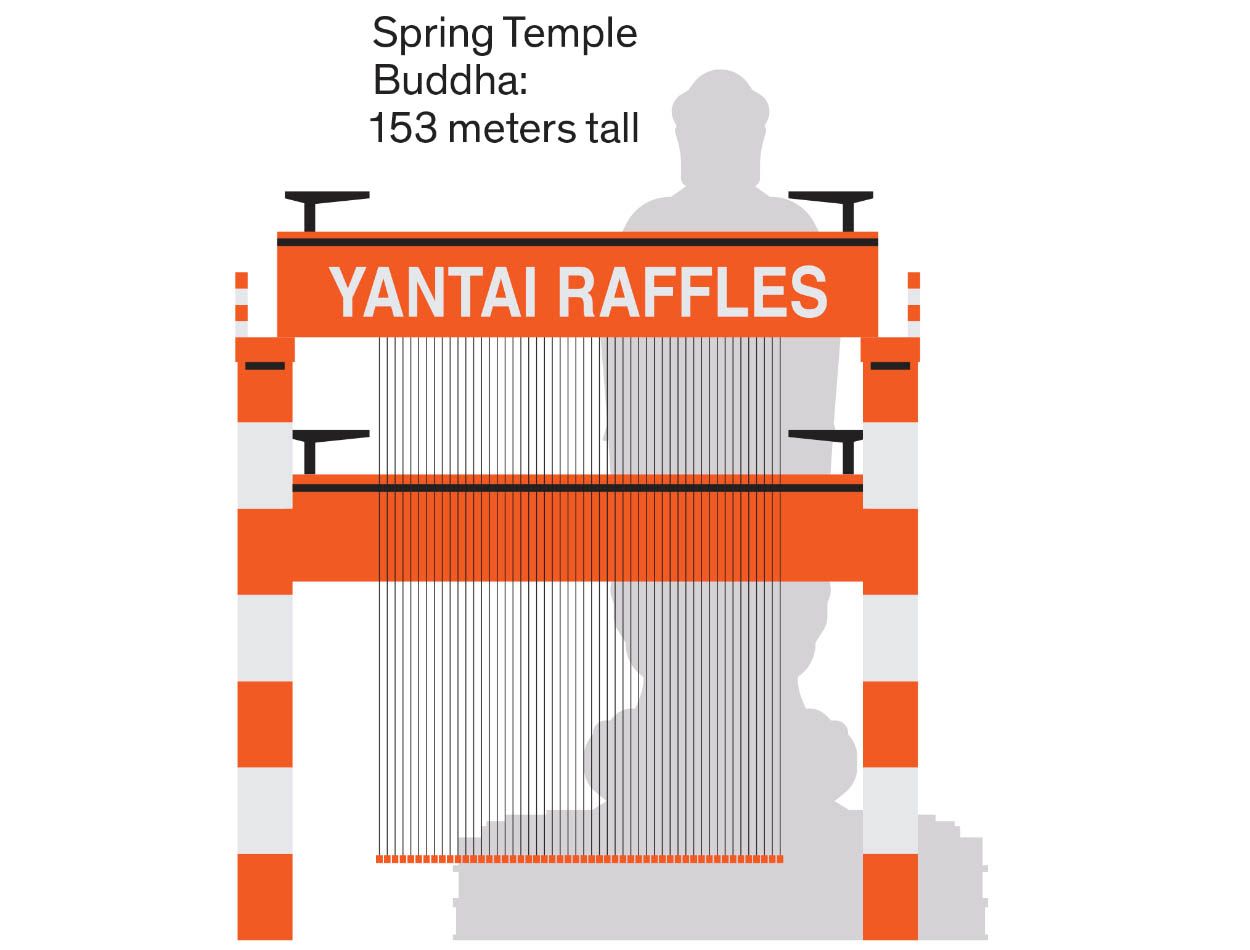

Archimedes said that a man with a lever, properly placed, could move the world; small modern cranes can lift a giraffe. And some models stand tall enough to hoist sizable weights to the top of some rather famous monuments.

UNIC URW-094: Smallest Mobile Crane

UNIC URW-094: Smallest Mobile Crane Built: 2009

Capacity: 1 metric ton

Maximum lift height: 5.7 meters

Radius: 7 meters

LIEBHERR LTM 11200-9.1: The Most Powerful Mobile Crane

LIEBHERR LTM 11200-9.1: The Most Powerful Mobile Crane Built: 2014

Capacity: 1,200 metric ton

Maximum lift height: 188 meters

Telescopic boom: 18.3 to 100 meters

KROLL K10000: The Most Powerful Tower Crane

KROLL K10000: The Most Powerful Tower Crane Built: 1976

Capacity: 120 metric tons

Height: 121 meters

Area covered: 3 hectares (30,350 square meters)

TAISUN: The Most Powerful Gantry Crane

TAISUN: The Most Powerful Gantry Crane Built: 2019

Capacity: 20,000 metric tons

Height: 133 meters

Maximum lift height: 80 meters

Width: 120 meters

Length of rope: 48 kilometers

Illustrations: Francesco MuzziA crane can lift a burden, move it sideways, and lower it. These operations, which the Greeks employed when building marble temples 25 centuries ago, are now performed every second somewhere around the world as tall ship-to-shore gantry cranes empty and reload container vessels. The two fundamental differences between ancient cranes and the modern versions involve the materials that make up those cranes and the energies that power them.

The cranes of early Greek antiquity were just wooden jibs with a simple pulley whose mechanical advantage came from winding the ropes by winches. By the third century B.C.E., compound pulleys had come into use; these Roman trispastos provided a nearly threefold mechanical advantage-nearly, because there were losses to friction. Those losses became prohibitive with the addition of more than the five ropes of the pentaspastos.

The most powerful cranes in the Roman and later the medieval periods were powered by men treading inside wheels or by animals turning windlasses in tight circles. Their lifting capacities were generally between 1 and 5 metric tons. Major advances came only during the 19th century.

William Fairbairn's largest harbor crane, which he developed in the 1850s, was powered by four men turning winches. Its performance was further expanded by fixed and movable pulleys, which gave it more than a 600-fold mechanical advantage, enabling it to lift weights of up to 60 metric tons and move them over a circle with a 32-meter diameter. And by the early 1860s, William Armstrong's company was producing annually more than 100 hydraulic cranes (transmitting forces through the liquid under pressure) for English docks. Steam-powered cranes of the latter half of the 19th century were able to lift more than 100 metric tons in steel mills; some of these cranes hung above the factory floor and moved on roof-mounted rails. During the 1890s, steam engines were supplanted by electric motors.

The next fundamental advance came after World War I, with Hans Liebherr's invention of a tower crane that could swing its loads horizontally and could be quickly assembled at a construction site. Its tower top is the fulcrum of a lever whose lifting (jib) arm is balanced by a counterweight, and the crane's capacity is enhanced by pulleys. Tower cranes were first deployed to reconstruct bombed-out German cities; they have diffused rapidly and are now seen on construction projects around the world. Typical lifting capacities are between 12 and 20 metric tons, with the record held by the K10000, made by the Danish firm Kroll Cranes. It can lift up to 120 metric tons at the maximum radius of 100 meters.

Cranes are also mainstays of global commerce: Without gantry quay cranes capable of hoisting from 40 to 80 metric tons, it would take weeks to unload the 20,000 standard-size steel containers that sit in one of today's enormous container ships. But put cranes together in a tightly coordinated operation involving straddle carriers and trucks and the job now takes less than 72 hours. And 20,568 containers were unloaded from the Madrid Maersk in Antwerp in June 2017 in the record time of 59 hours.

Without these giant cranes, every piece of clothing, every pair of shoes, every TV, every mobile phone imported from Asia to North America or Europe would take longer to arrive and cost more to buy. As for the lifting capacity records, Liebherr now makes a truly gargantuan mobile crane that sits on an 18-wheeler truck and can support 1,200 metric tons. And, not surprisingly given China's dominance of the industry, the Taisun, the most powerful shipbuilding gantry crane, can hoist 20,000 metric tons. That's about half again as heavy as the Brooklyn Bridge.

This article appears in the August 2020 print issue as Cranes (The Machines, Not Birds)."