Faster Microfiber Actuators Mimic Human Muscle

Robotics, prosthetics, and other engineering applications routinely use actuators that imitate the contraction of animal muscles. However, the speed and efficiency of natural muscle fibers is a demanding benchmark. Despite new developments in actuation technologies, for the most past artificial muscles are either too large, too slow, or too weak.

Recently, a team of engineers from the University of California San Diego (UCSD) have described a new artificial microfiber made from liquid crystal elastomer (LCE) that replicates the tensile strength, quick responsiveness, and high power density of human muscles. "[The LCE] polymer is a soft material and very stretchable," says Qiguang He, the first author of their research paper. "If we apply external stimuli such as light or heat, this material will contract along one direction."

Though LCE-based soft actuators are common and can generate excellent actuation strain-between 50 and 80 percent-their response time, says He, is typically "very, very slow." The simplest way to make the fibers both responsive and fast was to reduce their diameter. To do so, the UCSD researchers used a technique called electrospinning, which involves the ejection of a polymer solution through a syringe or spinneret under high voltage to produce ultra-fine fibers. Electrospinning is used for the fabrication of small-scale materials, to produce microfibers with diameters between 10 and 100 micrometers. It is favored for its ability to create fibers with different morphological structures, and is routinely used in various research and commercial contexts.

The microfibers fabricated by the UCSD researchers were between 40 and 50 micrometers, about the width of human hair, and much smaller than existing LCE fibers, some of which can be more than 0.3 millimeters thick. "We are not the first to use this technique to fabricate LCE fibers, but we are the first...to push this fiber further," He says. "We demonstrate how to control the actuation of the [fibers and measure their] actuation performance."

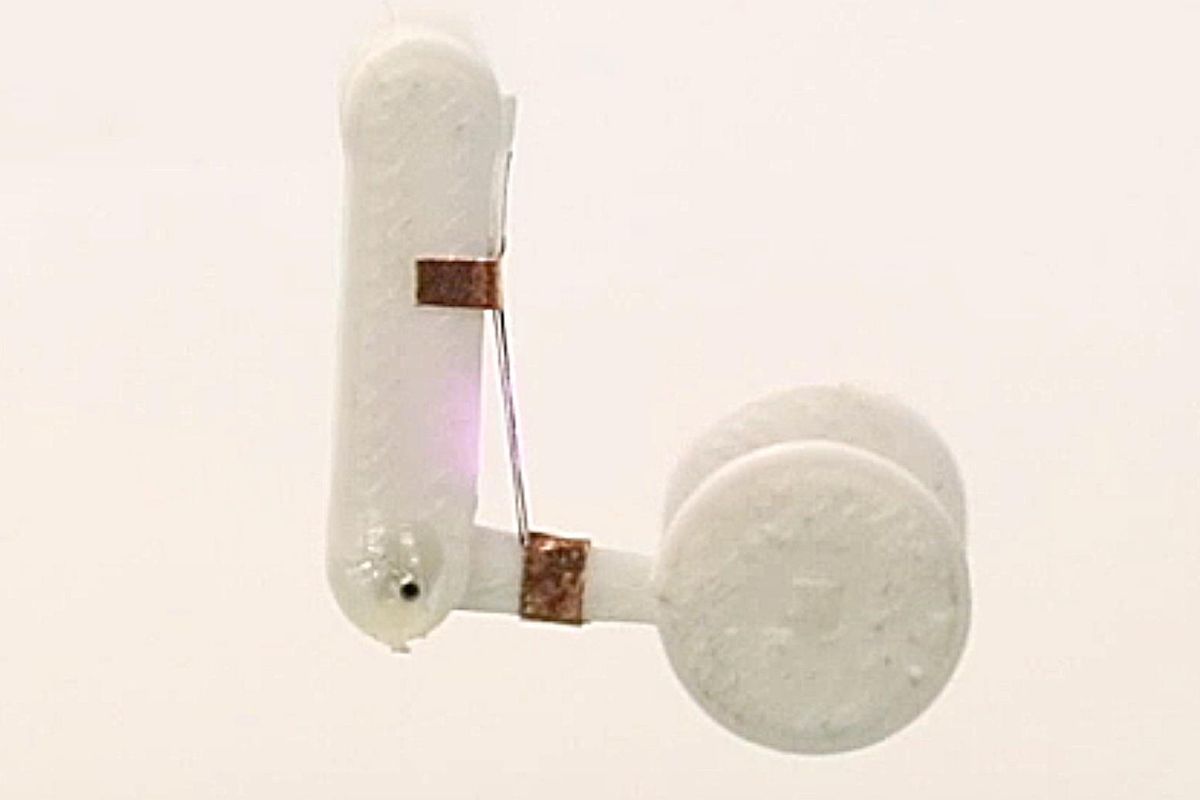

University of California, San Diego/Science Robotics

University of California, San Diego/Science Robotics

As proof-of-concept, the researchers constructed three different microrobotic devices using their electrospun LCE fibers. Their LSE actuators can be controlled thermo-electrically or using a near-infrared laser. When the LCE material is at room temperature, it is in a nematic phase: He explains that in this state, "the liquid crystals are randomly [located] with all their long axes pointing in essentially the same direction." When the temperature is increased, the material transitions into what is called an isotropic phase, in which its properties are uniform in all directions, resulting in a contraction of the fiber.

The results showed an actuation strain of up to 60 percent-which means, a 10-centimeter-long fiber will contract to 4 centimeters-with a response speed of less than 0.2 seconds, and a power density of 400 watts per kilogram. This is comparable to human muscle fibers.

An electrically controlled soft actuator, the researchers note, allows easy integrations with low-cost electronic devices, which is a plus for microrobotic systems and devices. Electrospinning is a very efficient fabrication technique as well: "You can get 10,000 fibers in 15 minutes," He says.

That said, there are a number of challenges that need to be addressed still. "The one limitation of this work is...[when we] apply heat or light to the LCE microfiber, the energy efficiency is very small-it's less than 1 percent," says He. "So, in future work, we may think about how to trigger the actuation in a more energy-efficient way."

Another constraint is that the nematic-isotropic phase transition in the electrospun LCE material takes place at a very high temperature, over 90 C. "So, we cannot directly put the fiber into the human body [which] is at 35 degrees." One way to address this issue might be to use a different kind of liquid crystal: "Right now we use RM 257 as a liquid crystal [but] we can change [it] to another type [to reduce] the phase transition temperature."

He, though, is optimistic about the possibilities to expand this research in electrospun LCE microfiber actuators. "We have also demonstrated [that] we can arrange multiple LCE fibers in parallel...and trigger them simultaneously [to increase force output]... This is a future work [in which] we will try to see if it's possible for us to integrate these muscle fiber bundles into biomedical tissue."