Social Construct’s computer-optimized buildings could shake construction industry’s foundations

Construction is one of the largest industries still resisting the call of the 21st century, its practitioners opting for decades-old but tried and true methods. Ben Huh, of Cheezburger fame, aims to modernize the planning and assembly of buildings with software-generated floorplans and rooms that fit together like LEGO bricks.

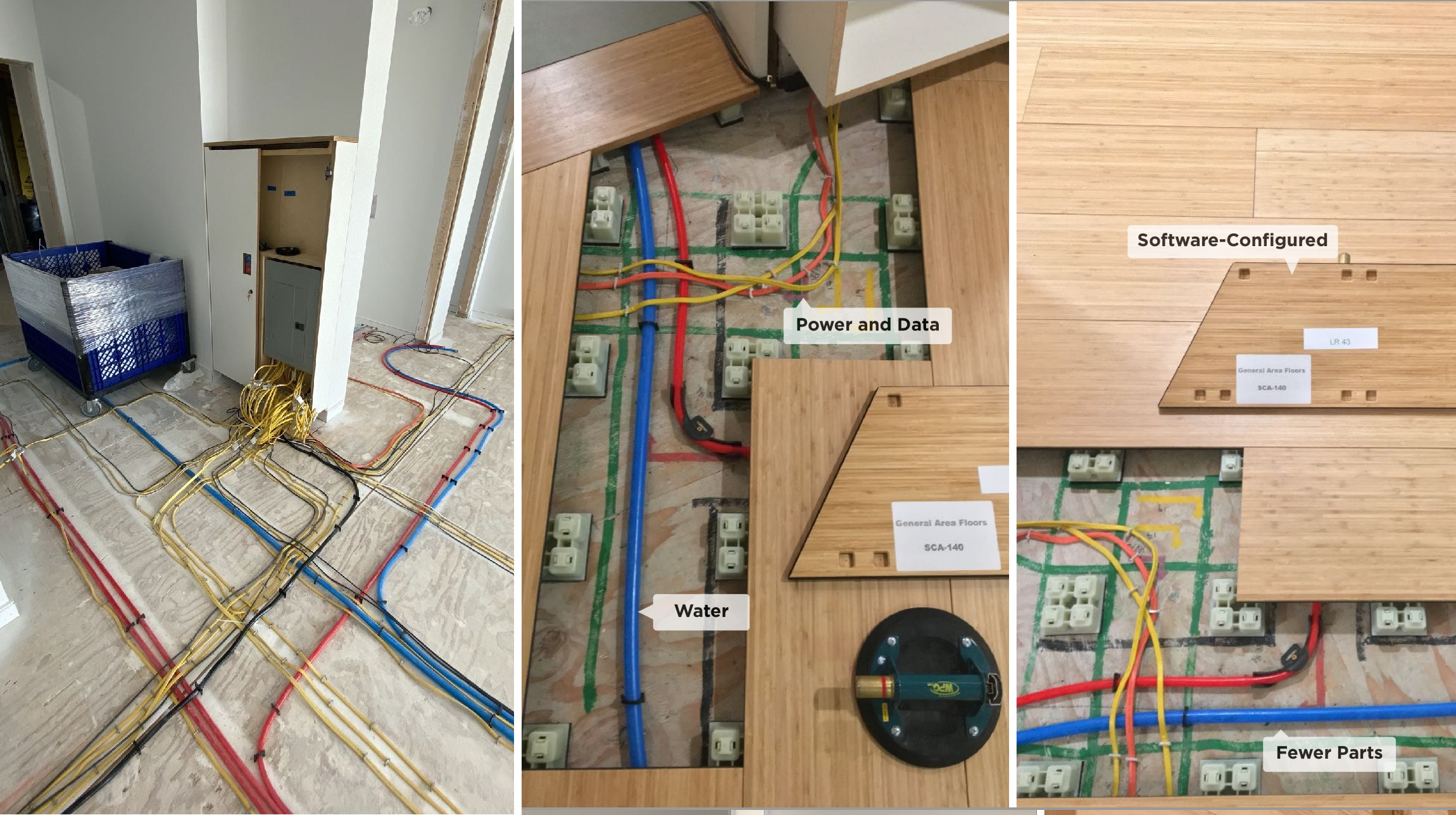

Huh's new company, Social Construct, handles everything from design to execution, leaving only the actual in-person work to construction contractors. By optimizing layouts, laying cables and pipes below floors instead of in walls, and standardizing both pieces and assembly, this new tech-informed method could reduce the time and cost of constructing a building by 20 to 30 percent.

The company emerged in 2017 out of a project at Y Combinator, where Huh worked after leaving web culture trailblazer Cheezburger. While researching the economics of construction, he was surprised at both the scale and dated nature of the industry.

Compared with the cost of manufacturing electronics or launching other large, multi-million-dollar endeavors, which have dropped precipitously, the costs and timeframes of construction have either remained fixed or increased for decades.

There have been productivity increases everywhere, but not in construction. It peaks in the '70s, then drops," he explained, illustrating the problem as follows: Imagine you have a 55-inch hole in your wall - it's cheaper today to buy a TV to cover the hole than to get it fixed."

It's unarguably true, but why should that be? The simple fact is that most construction-related work hasn't gotten any easier or more precise, and the jobs aren't so desirable as they once were. So labor costs go up along with the costs of ever more sophisticated buildings. But this just raises another question: Why hasn't the work gotten any easier or more precise?

It turns out that construction, although a huge industry, is a very fragmented one - and, understandably, rather risk-averse. Even if someone wanted to question the doctrines and practices by which buildings are made, they don't command the capital to do so.

People do stuff because it's what they were taught to do. No one has the millions in venture dollars to say, What if we did it different?' All these benefits show up, but then you have to reinvent part of the wheel, and companies have no reason to. There's just no reason a contractor would ever think about doing that," Huh explained.

The industry has effectively insulated itself against a great deal of innovation with an if it ain't broke, don't spend millions of dollars fixing it" attitude. It would take a venture-backed newcomer to upend the conventions that have held construction costs and methods in stasis for decades. So at least is Huh's hypothesis, and he believes that Social Construct is that newcomer.

Computational constructionHuh recalls his team questioning the status quo: We wondered, could we build a whole building out of precisely made parts, the way you'd build a plane?"

Turns out people have made attempts a few times, even before CAD made the idea so attractive. They tried this in the 70s," Huh said. What they found out was they could never get the parts to fit. The designs assumed an idealized space - exactly 10 feet or whatever. but it's never quite 10 feet, the parts just aren't that precise. Half an inch of error over 10 feet is actually pretty good. So everyone works around each other, which means the parts have to be cut to fit. Flexibility is more important than precision."

Where Social Construct's process diverges from the industry norm is at the point where the general shape and purpose of the building and its floors have been decided. For instance, it may be a largely triangular building with flat corners, the elevator in the center, and with three one-bedroom and one two-bedroom apartments on each floor.

That sort of design can be roughed out by an architect in a few hours, but the specifics of where exactly everything goes, from water fixtures to electrical lines, can take much longer. So that's where the computer takes over.

Image Credits: Social Construct

You could call it an AI, but Huh has deliberately shunned the term to avoid any suspicion of trying to take a ride on that particular hype train. Working from that level of detail, the Social Construct system plans out every aspect of the construction, optimizing the layout for a variety of parameters.

There are three key aspects:

First, construction uses pre-fabricated assemblies," of which there are about a hundred types total: walls with kitchen cabinets, walls with holes for shower fixtures, lighting and so on. These pieces can be carried by a single person or at most two, and snap into place onto the framing. This minimizes the chance that there will be any unusual dimensions or requirements that mean this wall has to be extra thick, or you need an extra length of piping to supply the bathroom sink. It also makes assembly and repair work simple. Where there are normal walls or non-standard widths, ordinary drywall is used.

Second, all the pipes, cables, and assorted in-wall infrastructure has been moved under the floor, the routes pre-determined by the computer. It all goes in a tiny space below the floorboards - which provides better sound and heat insulation as a side benefit. This further simplifies construction, as there is no need to adapt or improvise the angles, lengths, and other aspects of water or electrical work. The light switches don't even need to be connected, as they're wireless and kinetically powered.

Image Credits: Social Construct

Third, the layout is calculated to minimize the possibility of variance in measurements or construction. Cuts can never be perfect and microscopic errors add up so 20 feet hallway in the design document might actually need to be 20 feet and a quarter inch. The computer knows this and plans around it, avoiding situations that tend to create that type of variance wherever possible and allowing for last-minute adjustments when it's inevitable.

So the sequence of events is that the basic shell" of the building including all the usual stacks and structural pieces gets built as normal - that part doesn't change at all. Once it's done, the team measures the actual dimensions inside very, very carefully, which lets the computer design for exactly that space. Then the walls are raised per the generated plan, the cables are laid according to the same, the assemblies are carted in and click into place, and finally the hardwood floors are installed, with the pieces cut to fit what little differences from the plan have emerged.

Image Credits: Social Construct

We compared this to a conventionally built building, and we're seeing that we can save 20 percent on construction costs," Huh said - and considering construction is about two thirds of a building's entire budget, that may be saving tens of millions right off the bat. The Social Construct building was also finished 2 months faster.

Faster work may sound like less hours for subcontractors and the like, but Huh said they're emphasizing that lower costs and quicker work mean more productivity, so take-home pay is comparable but jobs will be easier and more numerous.

[gallery link="file" ids="2016602,2016603,2016598,2016600,2016601,2016599"]

It's important to note that Social Construct isn't actually getting into the contracting side of things. The plan is to partner with, train, and certify contractors so that they can scale more like a platform than a boots-on-the-ground company - Which makes us venture-backable," Huh noted.

Right now the first building built with these methods has been sold and the company is looking for its next site, local partner, and land owner - and so they decided to exit stealth mode.

Social Construct already has about $17 million in funding, from Floodgate, S28 Capital, Felicis, Founders Fund, and (of course," Huh said) Y Combinator. They'll be looking for more soon as they begin the process of truly scaling up, but it seems wise to have remained quiet until there was a whole building they could point to and say, look, it works!"

So if your dream was to live in a computer-designed building and apartment, you're slightly late - but it sounds like this will be the first of many.