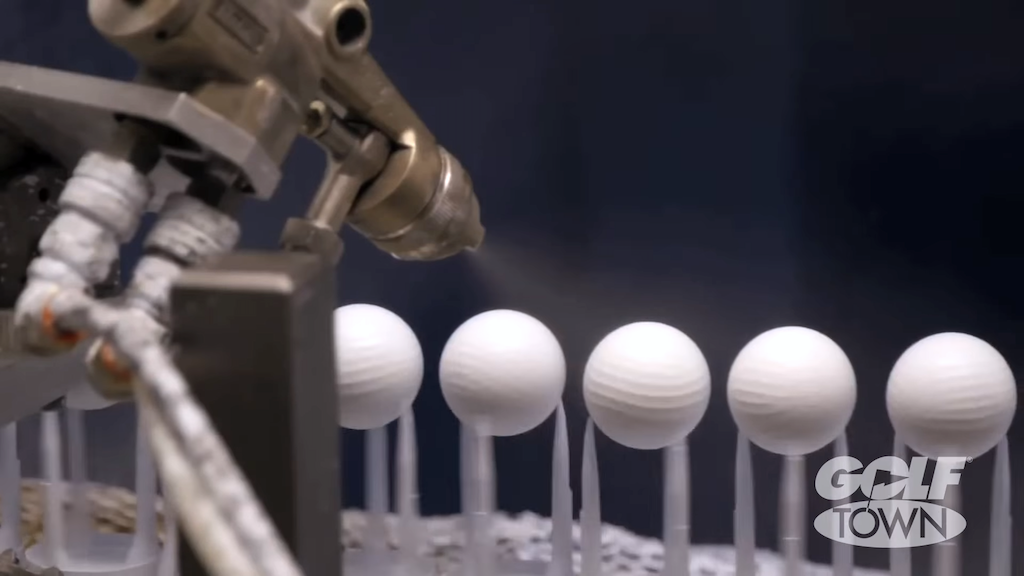

How Titleist Pro V1 Golf Balls Are Made

by Lori Dorn from Laughing Squid on (#5CEGA)

Golf Town Channel went inside the Titleist Ball Plant 3 to see firsthand how their signature Pro V1 and Pro V1x golf balls are made. The fully automated process shows how flat pieces of synthetic rubber are then shaped, ground, given dimples, painted, polished, labeled, and boxed for retail sale all in one place.

We take you inside Titleist's Ball Plant 3, home of the Pro V1 and Pro V1x golf ball.

View this post on Instagram

via The Awesomer

Related PostsA Father and Son Team Cut Open Hundreds of Golf Balls to See What's InsideWhy Dimples Are So Important to Golf Ball DesignCrazy Golf Shot Off of a Fence Post Lands Inches Away from the HoleThe Celestial Beauty of Colorful Golf Ball GutsWhat the Inside of Golf Balls Looks LikeAn Inside Look at the Competitive World of Professional Mini GolfFollow Laughing Squid on Facebook, Twitter, and Subscribe by Email.

The post How Titleist Pro V1 Golf Balls Are Made first appeared on Laughing Squid.