Lego bricks are making science more accessible

Etienne Boulter walked into his lab at the Universite Cote d'Azur in Nice, France, one morning with a Lego Technic excavator set tucked under his arm. His plan was simple yet ambitious: to use the pieces of the set to build a mechanical cell stretcher.

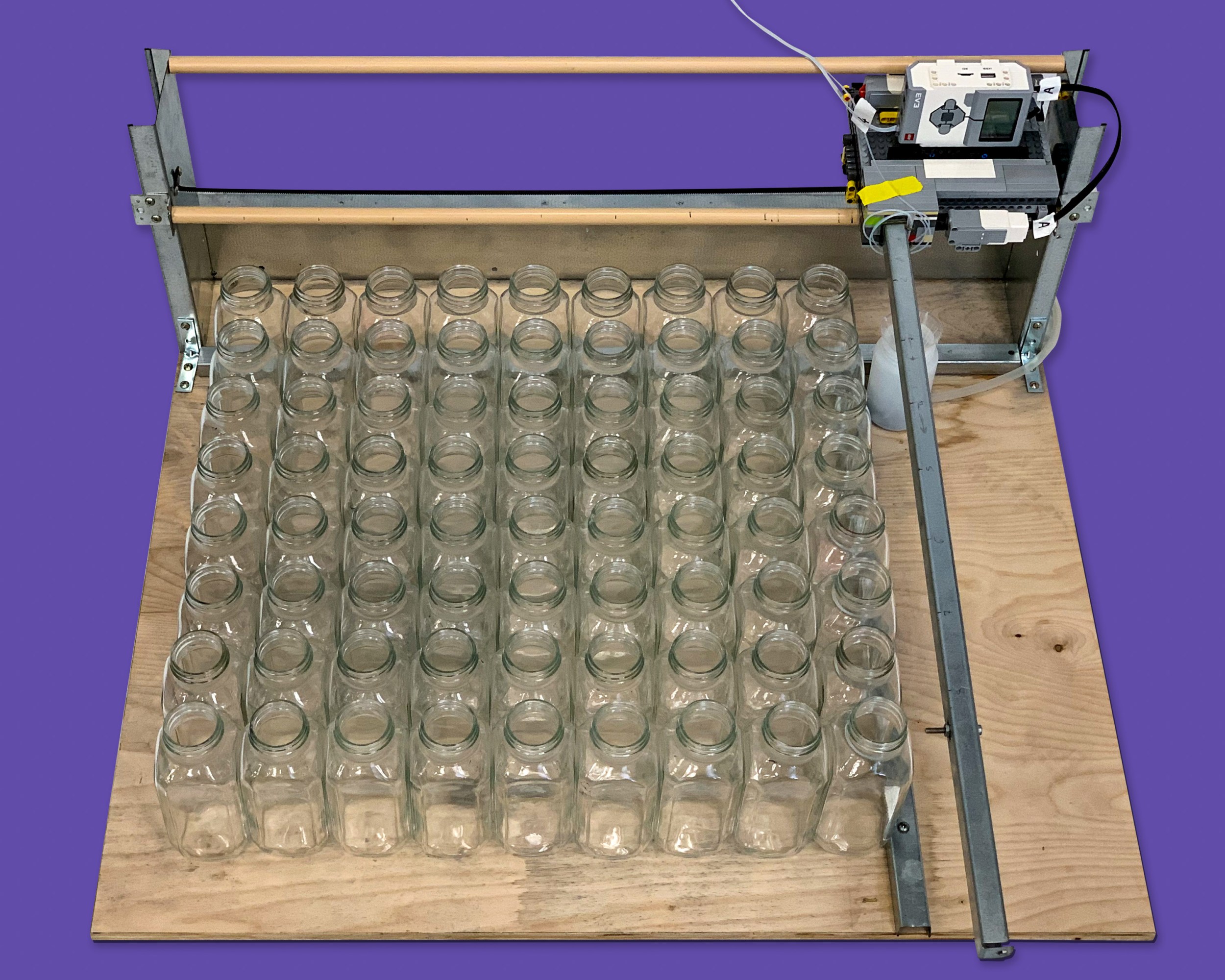

Boulter and his colleagues study mechanobiology-the way mechanical forces, such as stretching and compression, affect cells-and this piece of equipment is essential for his research. Commercial cell stretchers cost over $50,000. But one day, after playing with the Lego set, Boulter and his colleagues found a way to build one out of its components for only a little over $200. Their Lego system stretches a silicone plate where cells are growing. This process causes the cells to deform and mimics how our own skin cells stretch.

Sets like these are ideal to repurpose, says Boulter: If you go to Lego Technic, you have the motors, you have the wheels, you have the axles-you have everything you need to build such a system." Their model was so successful that 10 different labs around the world contacted him for the plans to build their own low-cost Lego stretchers.

Boulter is one of many researchers turning to Lego components to build inexpensive yet extremely effective lab equipment. The bricks themselves are durable and manufactured with tight tolerances. Lego's offerings include sensors that can detect various colors, perceive rotational motion, and measure the distance to an object. These DIY tools are acreative and affordable solution for working scientists who are trying to keep costs down.

ELIZABETH FERNANDEZ

ELIZABETH FERNANDEZTake, for example, the Lego chromatographer designed by Cassandra Quave and her husband, Marco Caputo, both at Emory University. Quave is an ethnobotanist who leads a research group dedicated to documenting traditional medicines. Her team travels deep into forests and jungles around the world, collecting samples of leaves, berries, and seeds that they evaluate for their potential pharmaceutical value. To isolate chemical compounds from the plant samples, Quave makes use of a meticulous process called chromatography, in which liquid distilled from the plant is passed over a tube filled with a material such as a silica gel.

Timing in chromatography needs to be very exact, with small amounts of liquid being added at precise moments. Waiting for these moments is not the best use of a graduate student's time. This is exactly what Quave thought when she walked into the lab one day and saw her PhD student Huaqiao Tang holding a test tube and watching the clock. This is crazy!" Quave said, laughing. We can come up with a better solution!"

When Quave told Caputo of her problem, he brought in Legos culled from their four children's massive collection and had his students see what they could do with them. They came up with a robotic arm that could make repeated precise movements, gradually adding small fractions of liquid to test tubes in order to isolate compounds within the plant tissue. The device was so accurate in its movements, Quave says, that spontaneous crystals formed, something that occurs only in very pure substances.

Ethnobotanist Cassandra Quave distills molecules from plants using a Lego chromatographer that she designed with her husband, researcher Marco Caputo.

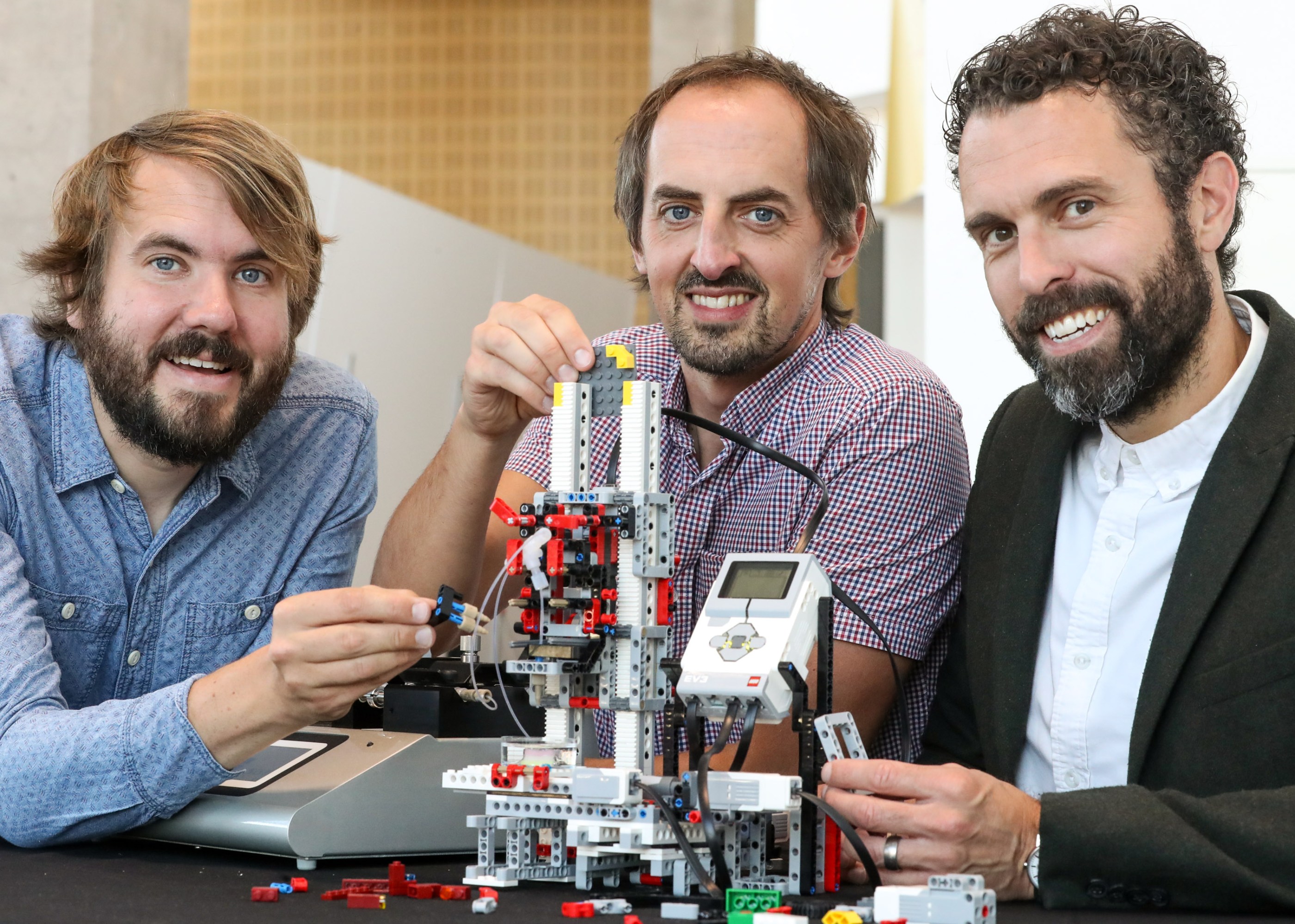

At Cardiff University in Wales, Christopher Thomas, Oliver Castell, and Sion Coulman had similar success building an instrument capable of printing cells. The researchers study skin diseases, lipids (fatty compounds) in the body, and wound healing. Ethically obtained samples are hard to find, so they created a 3D bioprinter out of Lego pieces that is capable of printing" a human skin analogue, laying down layers of bio-ink that contains living cells. These printers normally cost over a quarter of a million dollars, but they built their version for a mere $550. At first, their colleagues were skeptical that components typically treated as toys could be used in such a professional setting, but after seeing the printer at work, they were quickly convinced. The team made national news, and other groups replicated the model in their own labs.

At Cardiff University, Christopher Thomas, Oliver Castell, and Sion Coulman built an instrument capable of printing cells. Groups around the world have already replicated their design.COURTESY OF CARDIFF UNIVERSITY

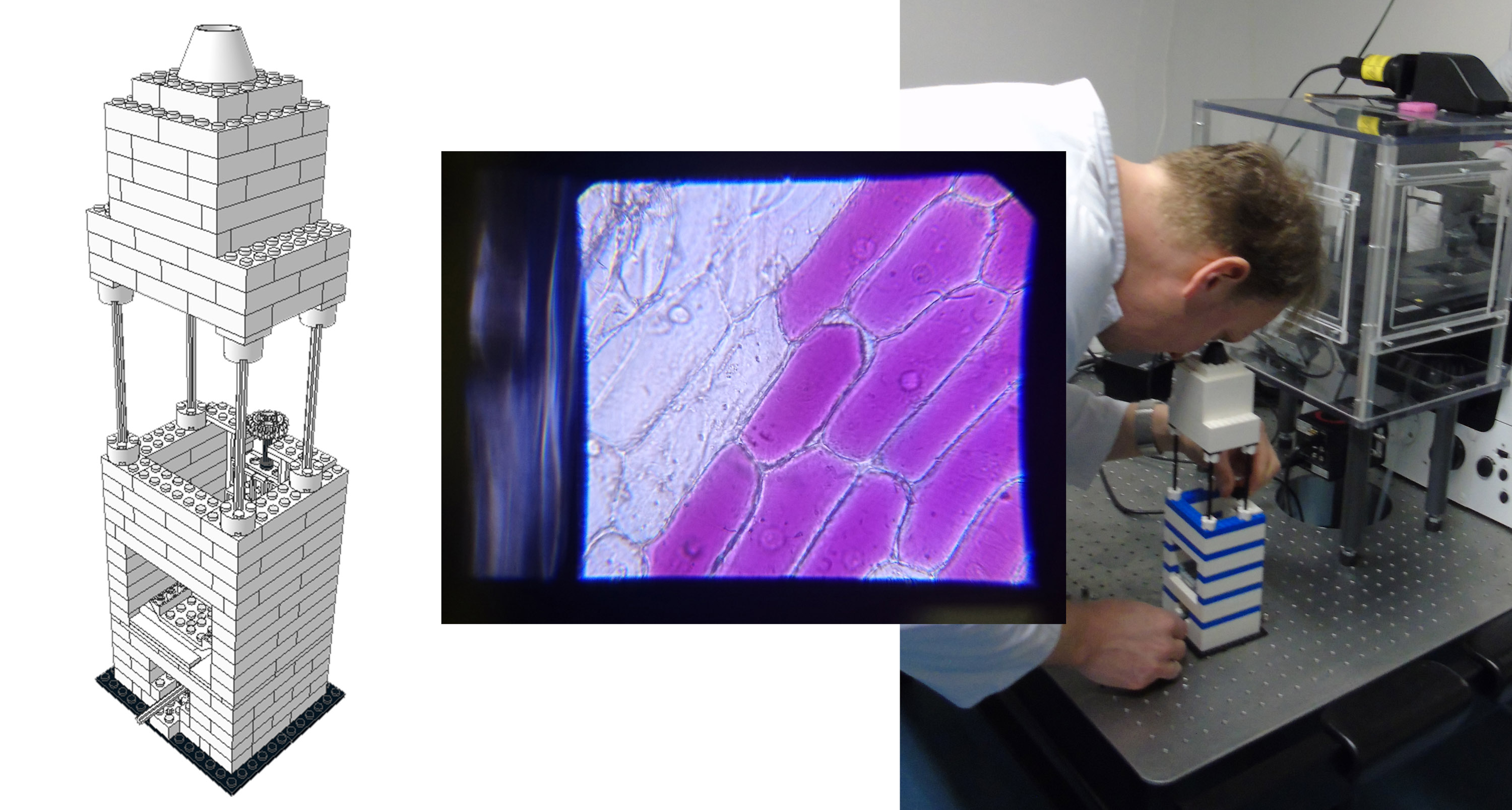

At Cardiff University, Christopher Thomas, Oliver Castell, and Sion Coulman built an instrument capable of printing cells. Groups around the world have already replicated their design.COURTESY OF CARDIFF UNIVERSITYSome scientists are devising tools to take into the classroom. Timo Betz of the University of Gottingen in Germany came up with the idea of building a Lego microscope one day while watching his son, Emil, then eight, play. Betz was scheduled to speak about science at a local school that afternoon but was reluctant to take his own lab-grade microscope into the classroom. His son was immediately on board. Let's do this!" he told his dad. Together with Bart Vos, a colleague at the university, they built a microscope that consisted entirely of Lego pieces, with the exception of two optical lenses. Their plans, which they've made available to the public, can be used by students as young as 12 to learn the basic concepts of optics.

Timo Betz of the University of Gottingen designed and built a working microscope entirely from Lego pieces.COURTESY OF TIMO BETZ

Timo Betz of the University of Gottingen designed and built a working microscope entirely from Lego pieces.COURTESY OF TIMO BETZMany of these scientists make their models open source, providing them to interested groups or publishing the plans on GitHub or in papers or so that other labs can make their own versions. This is great for researchers the world over, especially those with limited funding-whether they're new faculty members, scientists at smaller universities, or people working in low-income countries. It's how a small plastic brick is making science more accessible to all.

Elizabeth Fernandez is a freelance science writer.