Oncor’s System Operating Services Facility, Lancaster, Texas

Looking to ensure reliable power for a critical facility-as well as move the needle on microgrid technology-Texas's largest transmission company went all-in on a state-of-the-art demonstration project that sets a new standard for future smart grid deployments.

Having a 100% uninterruptible power supply for a commercial facility is far from a unique requirement. Traditionally, meeting that need often began and ended with an emergency diesel generator, but with emissions regulations and fuel costs making diesel less attractive, other options such as microturbines and renewable generation have begun making inroads.

Quite a few commercial facilities sport their own solar panels, some of them even reaching megawatt scale. But it's one thing to generate renewable energy on site; it's quite another to be able to fall back on it when the grid goes down. Tying it all together into a flexible, integrated system that can operate cleanly and reliably regardless of the state of the larger grid has been a challenge because of high costs and the requirements of balancing intermittent renewable generation.

Texas transmission and distribution (T&D) company Oncor is ready to help its customers start rolling out those kinds of microgrids. And to help make it happen, Oncor went and built one of its own at its System Operating Services Facility (SOSF) outside Dallas. At about 1,000 kW, the SOSF microgrid is not especially large, but it's the way Oncor incorporated multiple types of renewable and conventional generation, energy storage, and sophisticated controls into a fast-responding, redundant, multi-layered system that earns it POWER's 2015 Smart Grid Award.

Breaking GroundOncor is the largest regulated electricity delivery firm in Texas and the sixth largest in the U.S. It serves approximately 7.5 million customers in more than 3 million homes and businesses across the state through 121,000 miles of distribution lines. As a grid operator, Oncor is barred from owning commercial generation; it must buy the electricity it sells its customers on the wholesale market.

The SOSF in Lancaster, just south of Dallas, is a mixed-use campus that primarily supports Oncor's environmental operations, where used components are recycled, repaired, and refurbished. It is also the site for Oncor's Advanced Metering System testing as well as a telecommunications operations center and transformer repair facility. The SOSF needs high reliability for its critical loads, as even occasional outages represent a problem. But rather than simply hook up more backup generators, Oncor decided to make the SOSF a test bed for the next generation of microgrid architecture it wants to help its customers deploy.

Most microgrids are developed from existing infrastructure and generation. The SOSF system is a mix of old and new, unique in that it was built from the ground up as a state-of-the-art microgrid integrating existing emergency generation with new solar, battery, and microturbine resources. In early 2014, Oncor was preparing to upgrade an environmental center at the Lancaster site, and senior management decided to take the opportunity to gain experience with operating and interacting with microgrids, as well as hardening the site against a loss of power.

"Although the penetration rate for distributed energy resources [DER] is relatively modest in Texas, we understand that they will be part of the grid at some point," Michael Quinn, Oncor's vice president and chief technology officer told POWER. "Oncor wants to understand their impact so we can appropriately plan and safely and reliably integrate them into the grid."

The site as a whole needed an overhaul, as piecemeal additions over the years had each been connected to the grid as new customers, rather than as part of a single system, Quinn explained, with each facility getting its own meter and only two of them having emergency generation.

"This led to rethinking the opportunity to turn the site into a microgrid, improve the reliability and operations on site during loss of grid power, while gaining the opportunity to understand DER better," Quinn said.

In June 2014, Oncor tapped S&C Electric Co. and Schneider Electric to help design and build the system. Ground was broken in September, and the first elements came online in January. Testing was conducted a month later, and the project was declared operational in March.

Start to finish, the SOSF microgrid was completed in an impressive nine months, and it was funded entirely by Oncor, without reliance on subsidies or credits.

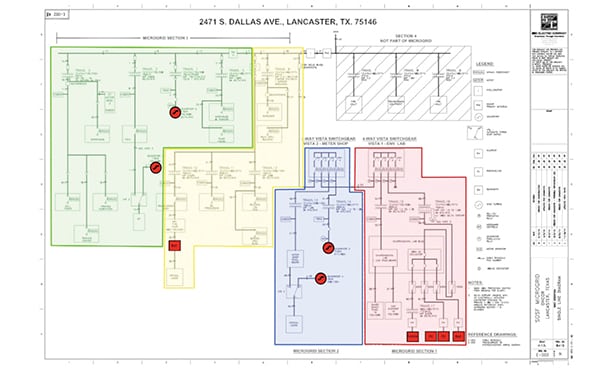

Multifaceted, Fast-MovingThe SOSF microgrid is actually four interconnected microgrids that can be controlled independently, but also operated in parallel, tandem, or combined into a single, larger system. One serves the telecommunications center, one serves the microgrid control center, and the other two serve less-critical assets on the SOSF campus (Figure 1).

The system begins with seven different generation resources:

a- Two 175-kW Caterpillar diesel generators

a- A 210-kW Caterpillar diesel generator

a- A 45-kW Cummins reciprocating propane engine (these first four were existing resources)

a- A 65-kW propane-powered Horizon/Capstone microturbine

a- A 104-kW Axium Solar carport-mounted solar photovoltaic (PV) array

a- A 2-kW Axium Solar ground-mounted PV array

Backing up these resources are two separate storage batteries:

a- A 200-kW/400-kWh Tesla lithium-ion Powerpack

a- A 25-kW/25-kWh S&C Purewave CES Community Energy Storage unit

The batteries can store energy from either the utility feed or any of the facility's generation resources (Figure 2). During normal operation, they provide the voltage signal for the site, smooth output from the solar panels, and control the microgrid frequency. Should grid power be lost, they're also the first generating resource to respond.

These resources are spread amongst the four microgrids-each one has either a generation resource, a battery, or both. The wide variety was intentional, because the system is designed as a test bed. According to David Chiesa, director of commercial & industrial and microgrid market segment for S&C Electric, "One of the goals was to get as many different technologies and different suppliers involved as possible and test integration." This was the reason, he said, that no one supplier was given more than one aspect of the project.

"Having diverse types and resources presented the typical real-world situation," Quinn said, "and we wanted that experience of integrating those into a single microgrid control platform. The added capability also allows support to a broader group of company operations during loss of grid power."

In the event of any hiccups, a combination of S&C's advanced distribution automation equipment and Schneider Electric's Microgrid Controller (MGC) use high-speed communications and distributed grid intelligence to detect any problems automatically. But it's not just a matter of deciding what distributed generation to turn on. Rather, the platform continuously monitors the system for faults: It can self-diagnose and isolate any issues, and it automatically reconfigures the rest of the microgrid to keep things running smoothly without the need for operator intervention.

Should grid power be lost altogether, S&C's IntelliRupter PulseCloser fault interrupter detects the loss and tests to see if the issue is temporary or permanent. If the fault is permanent, the system dynamically islands the facility. It then uses S&C's Scada-Mate CX Switches and Vista Underground Distribution Switchgear to reconfigure the distribution system while the MGC switches over to distributed generation.

With all of its resources running, the system can operate at peak 989-kW capacity for two hours, and-if the sun goes down and the batteries deplete-at 660 kW as long as fuel is available for the generators. A load-shedding algorithm can also shut down noncritical assets on the campus to keep the two critical microgrids operating as long as possible.

The microgrid control system does far more than simply switch on when the lights go out, however. It's designed to optimize the disparate generation resources to maximize solar PV energy usage and storage while minimizing overall energy costs. It does this using Schneider Electric's advanced grid control technologies, including the PowerLogic load preservation system and a new technology called StruxureWare Demand Side Operations (DSO). It's the DSO system that delivers economic optimization and dispatch of the generation resources.

Plenty of behind-the-meter storage and distributed generation solutions are capable of peak-shaving to avoid demand charges. DSO takes this to the next level and beyond by leveraging market pricing signals, weather and forecasting information, historical energy usage data, and real-time building information to continually seek out the lowest-cost power.

DSO is capable of looking at forward prices 15 minutes, an hour, or a day ahead and automatically determining when it's best to purchase power, sell it, or store it (the SOSF, as an Oncor facility, can't actually sell its power, but the system is capable of that, were it permitted to do so). This function is a significant benefit in a region like the Electricity Reliability Council of Texas (ERCOT), where peak power prices are allowed to rise as high as $9,000/kWh during critical grid periods.

A video with more information on the SOSF microgrid is available on YouTube: https://youtu.be/Hxr7ELpBcMs.

Leading the WayAs noted at the outset of this article, Oncor's ambitions go beyond just reliable power for the SOSF. It wants to use this system to test and demonstrate how microgrids can contribute to overall grid stability and, further, how they need not be a threat to a utility's bottom line.

At the center of the SOSF is an exhibit open for tours by customers and policymakers showing how the microgrid operates. Known as the Technology Demonstration and Education Center (TDEC), it consists of two parts: an immersion room and a demonstration center (Figure 3). In the immersion room, the microgrid is brought to life on seven screens through a video that highlights the history of the electric grid and the changes Oncor has made over time.

The demonstration center, which also serves as the microgrid control center, displays the new technology that keeps the system operating. It features a fully functioning SCADA representation of the microgrid to show how it reacts to a loss-of-power event or other fault. The demonstration center is not a mock-up-the actual switching devices, controls, communications, and software are on display.

"Oncor has a rich history of working collaboratively with its vendor partners, and this is a great opportunity to showcase those relationships in a state-of-the-art microgrid facility," Quinn said.

Microgrids, of course, present unique interconnection issues. Though they can firm the grid over the long term, in the short term, they force changes in utility operating procedures, especially during outages-reconnecting an islanded microgrid presents different safety and operational issues than reenergizing a customer without power.

"Improving power reliability and optimizing generation assets requires disruptive technologies that allow customers to work on and off the grid," Chiesa said. "Oncor's microgrid is showing the world how utilities can help their communities in the future."

Oncor intends to use the SOSF to learn the best ways of adapting to these changes, because it anticipates that similar critical pieces of infrastructure such as hospitals and 911 call centers, and large customers such as universities and manufacturing centers that want to ensure reliable power, will soon be deploying similar systems.

Storage ChallengesAnother reason Oncor wants to raise awareness of the possibilities of these systems is that, under current Texas law, utilities are handicapped by restrictions in the ERCOT market on who can own generation and sell electricity. It's not that Oncor and other utilities want to own generation; it's that new technologies like battery storage straddle the line between generation and load, and they can serve disparate grid functions in ways that are more efficient than existing solutions, yet those ways are not anticipated by current regulations. Addressing that problem will require regulatory reform.

Last fall, Oncor released a study conducted by the Brattle Group finding that the Texas grid could support up to 5 GW of distributed storage, assuming battery prices continue their downward trajectory (as they have since the study was released). Using that data, Oncor sought legislative changes that would be necessary for regulatory approval. Making it work economically would require these changes in the law so that the revenue stream from the generation side could be captured somehow. Oncor proposed a method by which utilities owning batteries could auction off a portion of the storage capacity to merchant generators, who would then be the ones to use that capacity to buy and sell electricity on the wholesale market. Oncor, meanwhile, would use the remaining capacity for reliability, quality of service, and deferral of traditional T&D assets.

Unfortunately for fans of energy storage, the proposal drew opposition from generators and other transmission operators concerned about changes in the market, and the 2015 Texas legislative session ended in June without any action being taken on the proposal. That means it will likely be a few more years-the Texas Legislature meets again in 2017-before any changes will be seen. In the meantime, Oncor intends to continue the policy discussions in hopes of reaching a consensus. No one expects the generation-transmission divide to be removed, but experts agree the regulatory environment has to be more battery-friendly for microgrids to reach their full potential.

Where the market will go remains to be seen, but many of those changes are likely to flow from Oncor's leadership with the SOSF microgrid. a-

- Thomas W. Overton JD is a POWER associate editor.

The post Oncor's System Operating Services Facility, Lancaster, Texas appeared first on POWER Magazine.