How Made In Space's 3-D Printer Could Revolutionize the Final Frontier

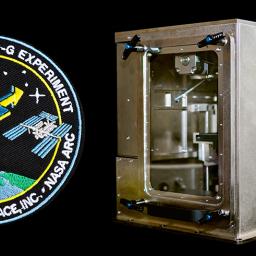

When the first 3-D printer designed to work in a weightless environment is sent up to the International Space Station - as early as next week! - it will mark one small step toward a giant leap for manufacturing in outer space.

When the first 3-D printer designed to work in a weightless environment is sent up to the International Space Station - as early as next week! - it will mark one small step toward a giant leap for manufacturing in outer space."Imagine if you're going to Mars, and instead of packing along 20,000 spare parts, you pack along a few kilograms of 'ink,'" NASA astronaut Reid Wiseman said in a video recorded in March before starting his stint on the station. "Now you don't even need to know what part is going to break. You can just print out that part. ... I really like that, and it'll be fun to play with that in orbit."

[Ed note: finally able to use the "printer" icon in a "space" article. Life is good.]

I'm going to have to add the National Academies to my RSS reader. I'm getting tired of all the hype in the media and am glad to listen to people who think carefully through problems before speaking.

(Great article, by the way - thanks for posting it).