Tissue created with microblood vessel network and integrated the tissue into mice - a major advance for bioprinting organs

by noreply@blogger.com (brian wang) from NextBigFuture.com on (#2GV3R)

New research, led by nanoengineering professor Shaochen Chen, addresses one of the biggest challenges in tissue engineering: creating lifelike tissues and organs with functioning vasculature -networks of blood vessels that can transport blood, nutrients, waste and other biological materials - and do so safely when implanted inside the body.

Researchers from other labs have used different 3D printing technologies to create artificial blood vessels. But existing technologies are slow, costly and mainly produce simple structures, such as a single blood vessel - a tube, basically. These blood vessels also are not capable of integrating with the body's own vascular system.

"Almost all tissues and organs need blood vessels to survive and work properly. This is a big bottleneck in making organ transplants, which are in high demand but in short supply," said Chen, who leads the Nanobiomaterials, Bioprinting, and Tissue Engineering Lab at UC San Diego. "3D bioprinting organs can help bridge this gap, and our lab has taken a big step toward that goal."

Chen's lab has 3D printed a vasculature network that can safely combine with a host network to circulate blood. The blood vessels branch out into many series of smaller vessels, similar to the blood vessel structures found in the body.

Chen's team developed an innovative bioprinting technology, using their own homemade 3D printers, to rapidly produce intricate 3D microstructures that mimic the sophisticated designs and functions of biological tissues. Chen's lab team has used this technology in the past to create liver tissue and microscopic fish that can swim in the body to detect and remove toxins.

Researchers first create a 3D model of the biological structure on a computer. The computer then transfers 2D snapshots of the model to millions of microscopic-sized mirrors, which are each digitally controlled to project patterns of UV light in the form of these snapshots. The UV patterns are shined onto a solution containing live cells and light-sensitive polymers that solidify upon exposure to UV light. The structure is rapidly printed one layer at a time, in a continuous fashion, creating a 3D solid polymer scaffold encapsulating live cells that will grow and become biological tissue.

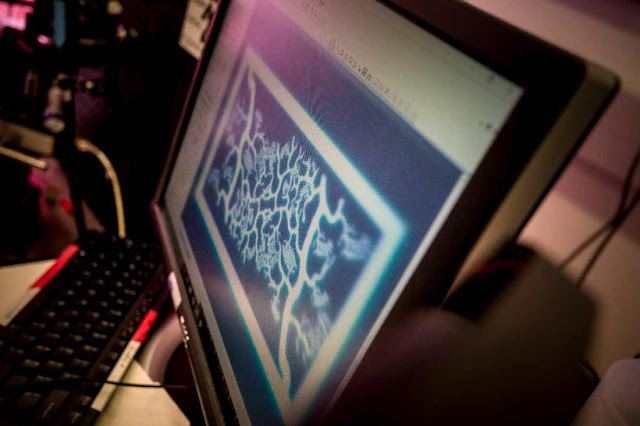

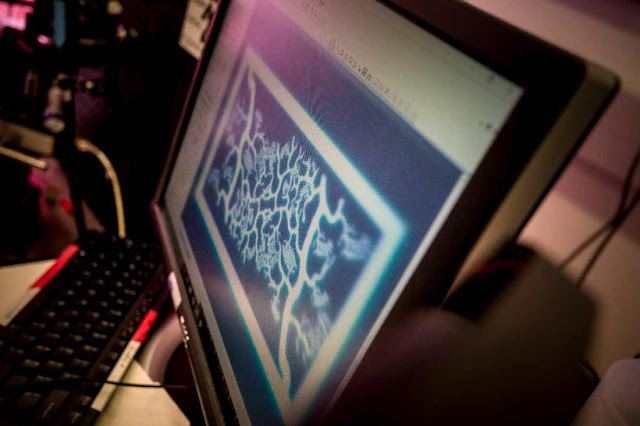

Digital model of a blood vessel network

Digital model of a blood vessel network

The system used digital 3-D designs from a computer to guide a 3-D printer's fabrication of blood vessels using biocompatible hydrogel materials. The device relied on ultraviolet light and about 2 million microscopic mirrors to guide the polymerization of the hydrogel materials into particular solid shapes. The designs from the computer dictated the angles of the microscopic mirrors to print the 3-D shape layer by layer.

The engineers created 2 versions of their 3-D blood vessel network. One was made using 2 hydrogels. The other was made with the 2 hydrogels plus 2 types of living cells. Each version measured about 4 mm by 5 mm (about the size of a pencil eraser) and was only 0.6 mm thick.

3-D printed blood vessels made with living cells (green and purple). Chen laboratory, Biomaterial

3-D printed blood vessels made with living cells (green and purple). Chen laboratory, Biomaterial

Biomaterials - Direct 3D bioprinting of prevascularized tissue constructs with complex microarchitecture

Read more

Researchers from other labs have used different 3D printing technologies to create artificial blood vessels. But existing technologies are slow, costly and mainly produce simple structures, such as a single blood vessel - a tube, basically. These blood vessels also are not capable of integrating with the body's own vascular system.

"Almost all tissues and organs need blood vessels to survive and work properly. This is a big bottleneck in making organ transplants, which are in high demand but in short supply," said Chen, who leads the Nanobiomaterials, Bioprinting, and Tissue Engineering Lab at UC San Diego. "3D bioprinting organs can help bridge this gap, and our lab has taken a big step toward that goal."

Chen's lab has 3D printed a vasculature network that can safely combine with a host network to circulate blood. The blood vessels branch out into many series of smaller vessels, similar to the blood vessel structures found in the body.

Chen's team developed an innovative bioprinting technology, using their own homemade 3D printers, to rapidly produce intricate 3D microstructures that mimic the sophisticated designs and functions of biological tissues. Chen's lab team has used this technology in the past to create liver tissue and microscopic fish that can swim in the body to detect and remove toxins.

Researchers first create a 3D model of the biological structure on a computer. The computer then transfers 2D snapshots of the model to millions of microscopic-sized mirrors, which are each digitally controlled to project patterns of UV light in the form of these snapshots. The UV patterns are shined onto a solution containing live cells and light-sensitive polymers that solidify upon exposure to UV light. The structure is rapidly printed one layer at a time, in a continuous fashion, creating a 3D solid polymer scaffold encapsulating live cells that will grow and become biological tissue.

Digital model of a blood vessel network

Digital model of a blood vessel networkThe system used digital 3-D designs from a computer to guide a 3-D printer's fabrication of blood vessels using biocompatible hydrogel materials. The device relied on ultraviolet light and about 2 million microscopic mirrors to guide the polymerization of the hydrogel materials into particular solid shapes. The designs from the computer dictated the angles of the microscopic mirrors to print the 3-D shape layer by layer.

The engineers created 2 versions of their 3-D blood vessel network. One was made using 2 hydrogels. The other was made with the 2 hydrogels plus 2 types of living cells. Each version measured about 4 mm by 5 mm (about the size of a pencil eraser) and was only 0.6 mm thick.

3-D printed blood vessels made with living cells (green and purple). Chen laboratory, Biomaterial

3-D printed blood vessels made with living cells (green and purple). Chen laboratory, BiomaterialBiomaterials - Direct 3D bioprinting of prevascularized tissue constructs with complex microarchitecture

Read more