Relativity Space has big dreams. Is the company for real?

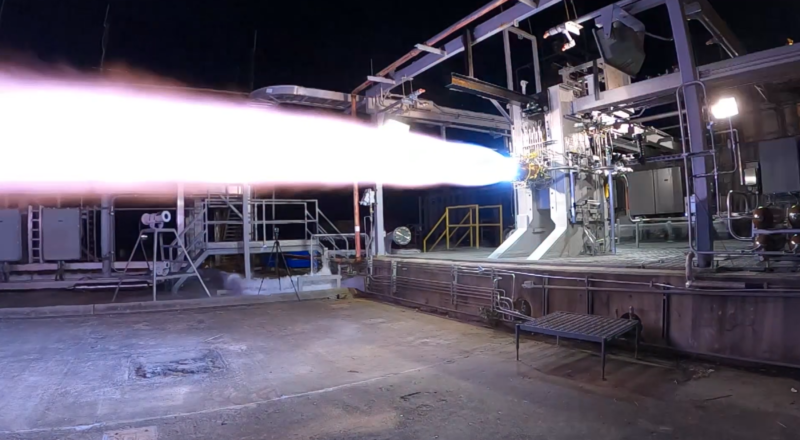

Enlarge / Relativity Space tests a component of its Aeon engine in December at the E-2 test stand at Stennis Space Center in Mississippi. (credit: Relativity Space)

STENNIS SPACE CENTER, Miss.-David Giger bounded up 26 steel steps and emerged onto a rocket engine test platform. Off to his left, an unbroken stand of stately pine trees spread out over the Mississippi lowlands. Straight ahead, Giger had a clear view of two Apollo-era test stands through the trees. "It's quite a view," he said.

Here, the past meets the future. Giger and his company, Relativity Space, seek to create the most futuristic of rockets. To do so, they have come to the NASA center where rocket scientists tested the mighty engines that carried humans to the Moon half a century ago. Relativity has, over the last two years, steadily occupied more buildings and test stands here as part of its quest to build a rocket made almost entirely of 3D-printed parts. And if that goal were not fantastical enough, Relativity also seeks to automate as much of the rocket assembly and test process as possible, with the ultimate goal of additively manufacturing a rocket on the surface of Mars.

It is a wild, seemingly impossible dream-and yet it has captured the fancy of aerospace investors. Relativity has raised $185 million in four years and hired industry leaders like Giger. Now the program manager for the company's Terran 1 rocket, Giger spent more than a decade at SpaceX, where he led development of the Crew Dragon spacecraft. Today he superintends Relativity's plans for launching its first rocket into space, perhaps as early as next year. So as we stood on top of the E-4 test stand in Mississippi last month, I tried to do more than simply admire the view.

Read 44 remaining paragraphs | Comments