These self-morphing 3D wood shapes could be future of wood manufacturing

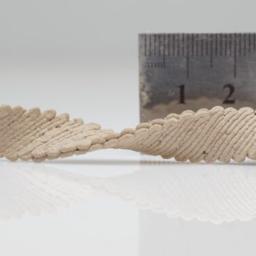

Scientists have shown how flat wooden shapes extruded by a 3D printer can be programmed to self-morph into complex 3D shapes.

Scientists from The Hebrew University of Jerusalem have created wood ink that can be extruded into flat wooden structures, self-morphing into complex 3D shapes as they dry and shrink. The researchers presented their research at last week's meeting of the American Chemical Society in Chicago. The technique could one day be used to make furniture or other wooden products that could be shipped flat to a destination and then dried to form the desired final shape.

As we've reported previously, developing novel shapeshifting materials is a very active area of research because there are so many promising applications, such as building artificial muscles-man-made materials, actuators, or similar devices that mimic the contraction, expansion, and rotation (torque) characteristics of the movement of natural muscle. The shape change comes about in response to an outside stimulus.

For instance, most artificial muscles are designed to respond to electric fields (such as electroactive polymers), changes in temperature (such as shape-memory alloys and fishing line), and changes in air pressure via pneumatics. In 2019, a team of Japanese researchers spiked a crystalline organic material with a polymer to make it more flexible, demonstrating their proof of concept by using their material to make an aluminum foil paper doll do sit-ups.