Fewer high paying oil rig jobs because of robots and process improvement

by noreply@blogger.com (brian wang) from NextBigFuture.com on (#2A3P2)

The robot on an oil drillship in the Gulf of Mexico made it easier for Mark Rodgers to do his job stringing together heavy, dirty pipes. It could also be a reason he's not working there today.

The Iron Roughneck, made by National Oilwell Varco Inc., automates the repetitive and dangerous task of connecting hundreds of segments of drill pipe as they're shoved through miles of ocean water and oil-bearing rock. The machine has also cut to two from three the need for roustabouts, estimates Rodgers, who took a job repairing appliances after being laid off from Transocean Ltd.

"I'd love to go back offshore," he says. The odds are against him. As the global oil industry begins to climb out of a collapse that took 440,000 jobs, anywhere from a third to half may never come back. A combination of more efficient drilling rigs and increased automation is reducing the need for field hands. And therein lies a warning to U.S. President Donald Trump, who has predicted a flood of new energy-sector jobs under his watch.

Automation, of course, has revolutionized many industries, from auto manufacturing to food and clothing makers. Energy companies, which rely on large, complex equipment for drilling and maintaining oil wells, are particularly well-positioned to benefit, says Dennis Yang, chief executive officer of Udemy, a company in San Francisco that trains workers whose careers were derailed by advanced machinery.

"It used to be you had a toolbox full of wrenches and tubing benders," says Donald McLain, chairman of the industrial-programs department at Victoria College in south Texas. "Now your main tool is a laptop." McLain, who worked as a rig hand for 25 years, is helping to retrain laid-off oil workers for more technical jobs.

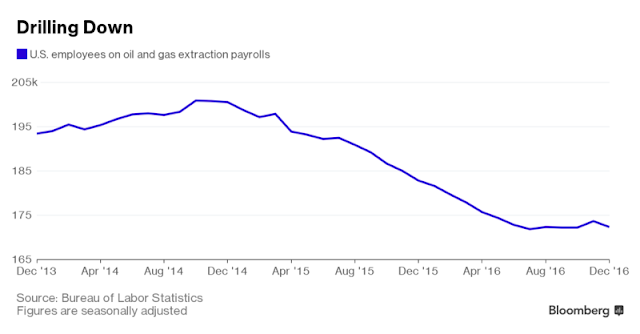

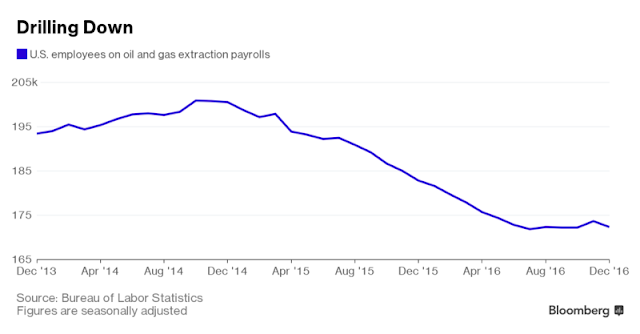

Job reductions to this point were caused by drop in drilling because of lower oil prices

Job reductions to this point were caused by drop in drilling because of lower oil prices

Read more

The Iron Roughneck, made by National Oilwell Varco Inc., automates the repetitive and dangerous task of connecting hundreds of segments of drill pipe as they're shoved through miles of ocean water and oil-bearing rock. The machine has also cut to two from three the need for roustabouts, estimates Rodgers, who took a job repairing appliances after being laid off from Transocean Ltd.

"I'd love to go back offshore," he says. The odds are against him. As the global oil industry begins to climb out of a collapse that took 440,000 jobs, anywhere from a third to half may never come back. A combination of more efficient drilling rigs and increased automation is reducing the need for field hands. And therein lies a warning to U.S. President Donald Trump, who has predicted a flood of new energy-sector jobs under his watch.

Automation, of course, has revolutionized many industries, from auto manufacturing to food and clothing makers. Energy companies, which rely on large, complex equipment for drilling and maintaining oil wells, are particularly well-positioned to benefit, says Dennis Yang, chief executive officer of Udemy, a company in San Francisco that trains workers whose careers were derailed by advanced machinery.

"It used to be you had a toolbox full of wrenches and tubing benders," says Donald McLain, chairman of the industrial-programs department at Victoria College in south Texas. "Now your main tool is a laptop." McLain, who worked as a rig hand for 25 years, is helping to retrain laid-off oil workers for more technical jobs.

Job reductions to this point were caused by drop in drilling because of lower oil prices

Job reductions to this point were caused by drop in drilling because of lower oil prices

Read more