Robotic Fabricator Can precisely lay brick and weld wire and next generation bot will be stronger and lighter

by noreply@blogger.com (brian wang) from NextBigFuture.com on (#2A95R)

A construction robot has to be powerful enough to handle heavy material, small enough to enter standard buildings, and flexible enough to navigate the terrain.

Researchers have developed a new class of robot capable of creating novel structures on a construction site. They call their new robot the In Situ Fabricator1 and today show what it is capable of.

The In Situ Fabricator is designed from the bottom up to be practical. It can build stuff using a range of tools with a precision of less than five millimeters, it is designed to operate semi-autonomously in a complex changing environment, it can reach the height of a standard wall, and it can fit through ordinary doorways. And it is dust- and waterproof, runs off standard electricity, and has battery backup. On top of all this, it must be Internet-connected so that an architect can make real-time changes to any plans if necessary.

Those are a tricky set of targets but ones that the In Situ Fabricator1 largely meets. It has a set of cameras to sense its environment and powerful onboard processors for navigating and planning tasks. It also has a flexible, powerful robotic arm to position construction tools.

To show off its capabilities, Giftthaler and co have used it to build a pair of structures in an experimental construction site in Switzerland called NEST (Next Evolution is Sustainable building Technologies). The first is a double-leaf undulating brick wall that is 6.5 meters long and two meters high and made of 1,600 bricks.

Even positioning such a wall correctly on a construction site is a tricky task. In Situ Fabricator1 does this by comparing the map of the construction site it has gathered from its sensors with the architect's plans. But even then, it must have the flexibility to allow for unforeseen problems such as uneven terrain or material sagging that changes a structure's shape.

"To fully exploit the design-related potentials of using such a robot for fabrication, it is essential to make use not only of the manipulation skills of this robot, but to also use the possibility to feed back its sensing data into the design environment," say Giftthaler and co.

The resulting wall, in which all the bricks are positioned to within seven millimeters, is an impressive structure.

The second task was to weld wires together to form a complex, curved steel mesh that can be filled with concrete. Once again, In Situ Fabricator1's flexibility proved crucial. One problem with welding is that the process creates tensions that can change the overall shape of the structure in unpredictable ways. So at each stage in the construction, the robot must assess the structure and allow for any shape changes as it welds the next set of wires together. Once again, the results at NEST are impressive.

In Situ Fabricator1 is not perfect, of course. As a proof-of-principle device, Giftthaler and co use it to identify improvements they can make to the next generation of construction robot. One of these is that at almost 1.5 metric tons, In Situ Fabricator1 is too heavy to enter many standard buildings-500 kilograms is the goal for future machines.

But perhaps the most significant problem is a practical limit on the strength and flexibility of robotic arms. In Situ Fabricator1 is capable of manipulating objects up to about 40 kilograms but ideally ought to be able to handle objects as heavy as 60 kilograms.

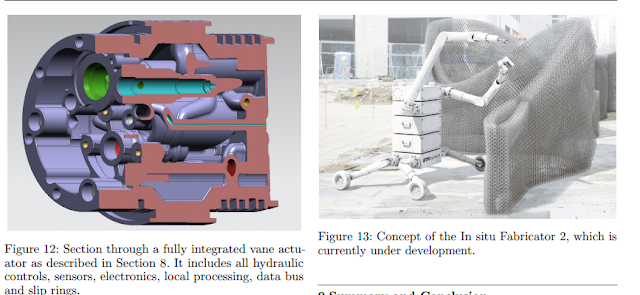

But that pushes it up against a practical limit. In Situ Fabricator1's arm is controlled by electric motors that are incapable of handling heavier objects with the same level of precision. What's more, electric motors are notoriously unreliable in the conditions found on construction sites, which is why most heavy machinery on these sites is hydraulic.

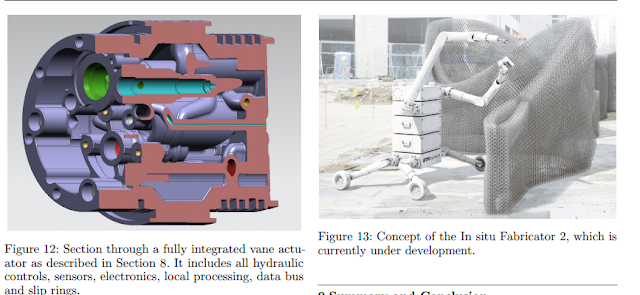

They have designed and built a hydraulic actuator that can control a next-generation robot arm while handling heavier objects more reliably and with the same precision. They are already using this design to build the next generation construction robot that they call In Situ Fabricator2, which should be ready by the end of this year.

Read more

Researchers have developed a new class of robot capable of creating novel structures on a construction site. They call their new robot the In Situ Fabricator1 and today show what it is capable of.

The In Situ Fabricator is designed from the bottom up to be practical. It can build stuff using a range of tools with a precision of less than five millimeters, it is designed to operate semi-autonomously in a complex changing environment, it can reach the height of a standard wall, and it can fit through ordinary doorways. And it is dust- and waterproof, runs off standard electricity, and has battery backup. On top of all this, it must be Internet-connected so that an architect can make real-time changes to any plans if necessary.

Those are a tricky set of targets but ones that the In Situ Fabricator1 largely meets. It has a set of cameras to sense its environment and powerful onboard processors for navigating and planning tasks. It also has a flexible, powerful robotic arm to position construction tools.

To show off its capabilities, Giftthaler and co have used it to build a pair of structures in an experimental construction site in Switzerland called NEST (Next Evolution is Sustainable building Technologies). The first is a double-leaf undulating brick wall that is 6.5 meters long and two meters high and made of 1,600 bricks.

Even positioning such a wall correctly on a construction site is a tricky task. In Situ Fabricator1 does this by comparing the map of the construction site it has gathered from its sensors with the architect's plans. But even then, it must have the flexibility to allow for unforeseen problems such as uneven terrain or material sagging that changes a structure's shape.

"To fully exploit the design-related potentials of using such a robot for fabrication, it is essential to make use not only of the manipulation skills of this robot, but to also use the possibility to feed back its sensing data into the design environment," say Giftthaler and co.

The resulting wall, in which all the bricks are positioned to within seven millimeters, is an impressive structure.

The second task was to weld wires together to form a complex, curved steel mesh that can be filled with concrete. Once again, In Situ Fabricator1's flexibility proved crucial. One problem with welding is that the process creates tensions that can change the overall shape of the structure in unpredictable ways. So at each stage in the construction, the robot must assess the structure and allow for any shape changes as it welds the next set of wires together. Once again, the results at NEST are impressive.

In Situ Fabricator1 is not perfect, of course. As a proof-of-principle device, Giftthaler and co use it to identify improvements they can make to the next generation of construction robot. One of these is that at almost 1.5 metric tons, In Situ Fabricator1 is too heavy to enter many standard buildings-500 kilograms is the goal for future machines.

But perhaps the most significant problem is a practical limit on the strength and flexibility of robotic arms. In Situ Fabricator1 is capable of manipulating objects up to about 40 kilograms but ideally ought to be able to handle objects as heavy as 60 kilograms.

But that pushes it up against a practical limit. In Situ Fabricator1's arm is controlled by electric motors that are incapable of handling heavier objects with the same level of precision. What's more, electric motors are notoriously unreliable in the conditions found on construction sites, which is why most heavy machinery on these sites is hydraulic.

They have designed and built a hydraulic actuator that can control a next-generation robot arm while handling heavier objects more reliably and with the same precision. They are already using this design to build the next generation construction robot that they call In Situ Fabricator2, which should be ready by the end of this year.

Read more